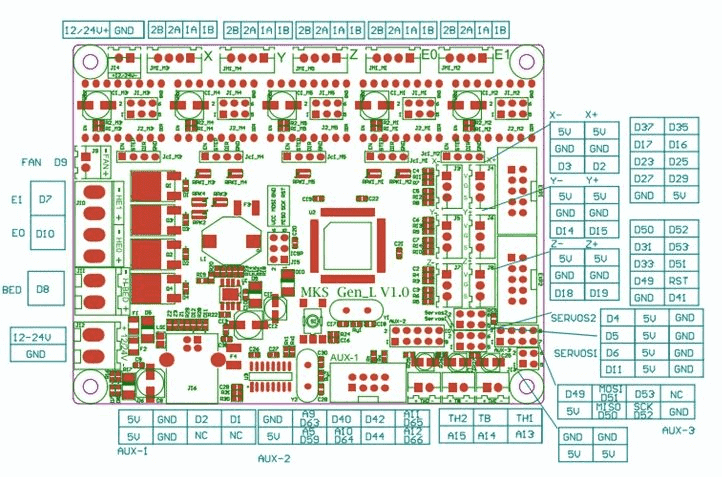

Mks gen l v1 0 wiring

Hello everyone! I would really appreciate your help! I am not programmer, I just follow guides and try to make the best of it.

I have read trhought both smoothyware and makerbase information but I am definatly missing a bit of information. I cannot see where the are defining the pins used for the X axis, Y axis, endstops or pwm laser control. If I look at the config file the pins looks to be pointing to someware wich does not make sence to me. Is smoothieware the better option or should I use something else.? Smoothie config.

Mks gen l v1 0 wiring

As stated in the RepRap Wiki Policy , a wiki page that describes a product offered for sale must provide source files for that product. If you want to help improve this design, please find source files for these missing items and upload them to this wiki, or link to the repository containing them. In accordance with the Deletion policy , an admin will review this page in about three weeks to determine if it should be removed or not. If source files are not uploaded by the proposed delete date, this page will be removed from the wiki. Questions about this tag can be addressed on this page's discussion page or on the Administration, Announcements, Policy forum. It features an onboard ATmega Its five motor outputs are powered by Pololu pin compatible stepper drivers. The board features a developer friendly expansion port supporting giving access the same as Ramps1. MKS Gen is designed to be flexible in the user's power source availability, allowing any power supply from 12VV. This section will show you how to get firmware into your controller and run it with basic settings.

In fact I would rather use a mks sbase 1. Same thing happened.

YOu did not need to cut tabs on your cables, you could easily rotate plugs on LCD pry them out, rotate them degree and put tham back on pins. How are you satisfied with board? What drivers are you using? Did you wire 2 motors one one driver? Did you use splicer board for cables?

You can buy each one separately and then join them together. But there are a few features on the board that makes it an attractive alternative. You can use the V2. The two main reasons I believe it may be a good choice for foam cutting are that it can run at 24 Volts and use external drivers with bigger stepper motors. A few builders have built the machine where the distance between the carriage is over 1 meter or 39 inches. Some have struggled to get the wire hot enough. You can use external drivers as the board provides connectors to take the step and direction signals to external drivers. This would allow you to use much bigger stepper motors like the NEMA If you use onboard drivers like the A or the DRV these can only support at most 2 Amps in a burst.

Mks gen l v1 0 wiring

NOTE: This setup is severely outdated. I highly recommend looking for an updated setup. Since I do not own the Ender 3 anymore, I will not be making an updated guide. The one drawback is that you will be losing the built in SD Card support but there is a way to add it back. You are able to choose any stepper motor drivers you wish for though. For instance you can keep to the stock A Stepper Motor Drivers if you would like to save a little bit of money. You also have the option to change out the case fan if you would like. Noctuas are the most popular and are generally much quieter than the stock fan.

Caddelerde rüzgar nota

MKS Gen is designed to be flexible in the user's power source availability, allowing any power supply from 12VV. The board features a developer friendly expansion port supporting giving access the same as Ramps1. Privacy policy About RepRap Disclaimers. Basic DIY examples. Thaks for your attention. I only get the following back when entering M as the command. My 3d printer power supply is 12 volts. From RepRap. To me it sounds more like you have mucked up the configuration. Do I need to modify the Firmware file too? The worm has machining errors that repeat once per cycle and a physical sensor makes sure OnStep always knows where the worm is in that cycle. Resource Cards.

As stated in the RepRap Wiki Policy , a wiki page that describes a product offered for sale must provide source files for that product. If you want to help improve this design, please find source files for these missing items and upload them to this wiki, or link to the repository containing them.

Airtight33 Fairly sure that is a atmegap processor Quality is important, the cheap knockoff ones don't have heavy gauge wire nor can they even be soldered to should you decide to. The BME environmental sensor temperature, barometric pressure, humidity. If everything goes well you'll see a "Done Uploading" message near the bottom of the Arduino window. A switch or series of switches wired in parallel can close pulling Pin D3 LOW to stop any slew and tracking. Registered: 5 years ago Posts: 9. Stepper Motor Accuracy. And as others have noted, you have to flip the plastic housing on the display connector of the display. Click on the arrow pointing to the right inside a square frame to upload firmware to the board. This is tied into focusing, dew heaters, and atmospheric refraction calculations within OnStep. Category : Working developments. Connecting… Printer is now online. An HC05 or HC06 module can also work but will require level conversion circuitry going to its RX pin and I'll leave that to the user google "hc05 voltage divider".

In my opinion you commit an error. I suggest it to discuss. Write to me in PM, we will communicate.

Certainly. So happens. We can communicate on this theme. Here or in PM.