Lovejoy coupling size chart

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application. This handbook is not a textbook. There are several of those in print which do a great job and are very useful for coupling designers, lovejoy coupling size chart.

Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death. Refer to this Lovejoy Catalog for proper selection, sizing, horsepower, torque range, and speed range of power transmission products, including elastomeric elements for couplings. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Lovejoy offers four types of elastomer designs to allow for additional flexibility in addressing specific application requirements.

Lovejoy coupling size chart

.

Straight-Side Type. When using reduced keys, torque capability must be carefully assessed.

.

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application. This handbook is not a textbook. There are several of those in print which do a great job and are very useful for coupling designers. What we are attempting to do is to provide down-to-earth useable knowledge. We want to arm you with information that you need to utilize the variety of styles that exist in flexible couplings to your best advantage and solve real world problems. Lovejoy has been manufacturing couplings since More importantly, we have the greatest breadth of coupling types offered by any single manufacturer in the world. Since couplings are our strategic focus, we feel you will find this handbook to be a valuable resource. A flexible coupling connects two shafts, end-to-end in the same line, for two main purposes. The first is to transmit power torque from one shaft to the other, causing both to rotate in unison, at the same RPM.

Lovejoy coupling size chart

Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death. Refer to this Lovejoy Catalog for proper selection, sizing, horsepower, torque range, and speed range of power transmission products, including elastomeric elements for couplings. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications.

Advisory parental png

Generally, the bore shaft diameter should be no greater than the length of shaft engagement in the hub. KEYWAY: A rectangular opening formed by matching rectangular slots cut axially lengthwise along both the coupling bore and shaft. Hardness is the key to improving wear resistance for longer life under increased friction from high speed or misalignment, because gear couplings typically wear out under load rather than break. The greatest parallel capability results from floating shaft, spacer and spindle versions, described later, which greatly lengthen the distance between flex planes. For an idea of how big the gear couplings can be made, the catalogs will show gear couplings up to size The legs of the spider protrude radially to become the cushions between the jaws. When a labyrinth seal coupling is matched to an O-ring-sealed coupling, the bore capability and torque may both be different despite the fact that their flanges match and bolt together. Steel can be treated in many ways to improve hardness and strength. Each design has strengths and weaknesses that must be taken into consideration because they can dramatically impact how well the coupling performs in the application. Metric Versus English Units. Therefore, load is transferred to the lower shaft and ultimately supported by a thrust bearing in that equipment.

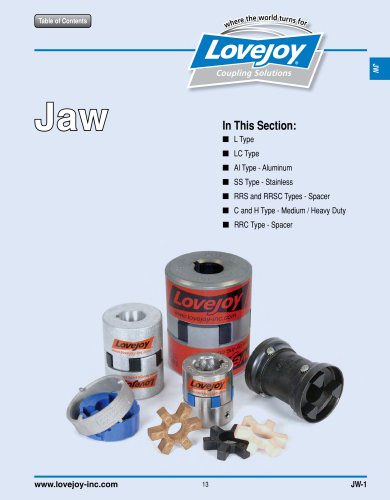

Each hub includes a set screw unless noted , which bites into your shaft to hold the coupling in place. A complete coupling consists of two hubs and one spider, or two hubs, one split spider, and one retaining ring all components sold separately.

Shaft Locking Devices catalog 24 Pages. Torsional tuning uses the dynamic torsional stiffness of the coupling to establish a low torsional critical speed. The next section will help provide the path among all the couplings for most types of rotating equipment. You just need to be careful to select a coupling type that has the proper level of torsional stiffness, in balance with the other performance features it provides. Backlash is not the same as torsional stiffness. The ideal shape for the elastomer is a cylinder, loaded radially. RunRight Products Catalog 68 Pages. Vari-Crown, which varies the curvature radius along the tooth flank, maintains greater contact area between teeth during misalignment compared with standard crowning, and reduces those stresses that cause wear. The load is carried in shear from its periphery to its center. Interference or Shrink Fits. This coupling is designed for use with vertical circulating pumps that need clearance adjustments in the impeller. When the coupling is not rotating, those two surfaces rest upon each other if it is a horizontal installation.

Instead of criticising write the variants is better.

I am sorry, that I interfere, but it is necessary for me little bit more information.

I am very grateful to you for the information. It very much was useful to me.