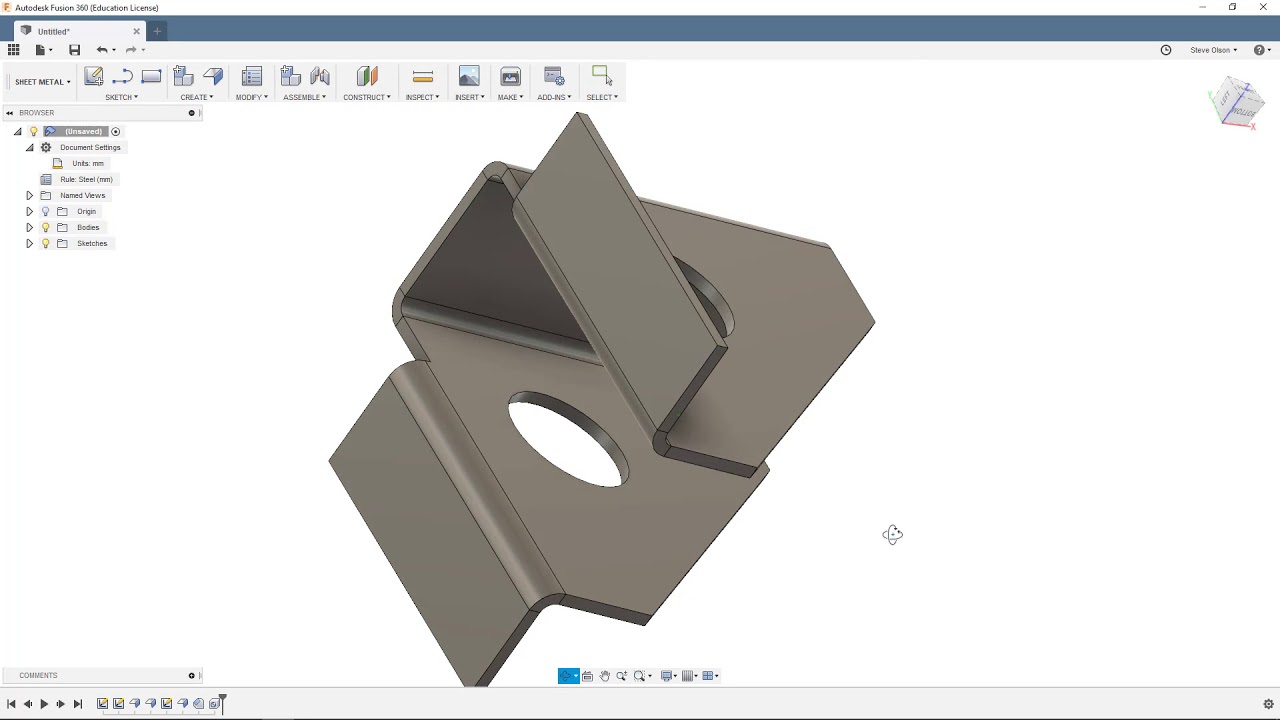

Fusion 360 sheet metal design

Forms Maintenance: Feb Thanks for your patience.

For manufacturing purposes, details like bend radii and relief sizes are usually the same throughout the part. You enter the values for these details, and then the software applies them as you design. For example, when you create a flange the bend is added automatically. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. These cookies enable us to provide enhanced functionality and personalization. They may be set by us or by third party providers whose services we use to deliver information and experiences tailored to you.

Fusion 360 sheet metal design

.

If you do not allow these cookies, some or all of these services may not be available fusion 360 sheet metal design you. Twitter We use Twitter to deploy digital advertising on sites supported by Twitter. You may experience a different version of our sites based on feature testing, or view personalized content based on your visitor attributes.

.

Sheet metal design software is the most critical component of sheet metal fabrication. Sheet metal is a common material across many industries, including automotive, industrial, and medical, because of its flexibility, durability, and tensile strength. As the name suggests, sheet metal is metal formed into thin, flat pieces using a portion of steel, aluminum, copper, brass, and other materials. It can be precisely cut and shaped into plates, sheets, or foils because of its unique characteristics. Sheet metal usually remains under 6 mm thick anything above 6 mm is a metal plate. You can measure this thickness in three different units: mils, millimeters, or gauges.

Fusion 360 sheet metal design

They each have their own benefits, but here are the two main reasons I would switch to using sheet metal design in Fusion What does this mean for you? Well, now with your subscription to Fusion , you will have access to all available functionality. In this post, we will take a deep dive into why you need to start using the sheet metal functionality inside Fusion

Fotos de tienda seur pickup madrid

New Relic We use New Relic to collect data about your behavior on our sites. AdWords Privacy Policy. Typepad Stats Privacy Policy. Improve your experience — allows us to show you what is relevant to you These cookies enable us to provide enhanced functionality and personalization. We collect data to better understand what actions you took before filling out a survey. Autodesk Fusion supports a wide range of manufacturing processes commonly used in sheet metal fabrication, including laser cutting, punching, bending, welding, and more. Google Optimize Privacy Policy. Autodesk Fusion streamlines the deformation-based sheet metal forming process. Amplitude Privacy Policy. Frequently asked questions FAQs. Your choice. We use the data that we provide to Bing to better customize your digital advertising experience and present you with more relevant ads. With cloud collaboration tools, multiple users to collaborate on the same design in real time.

Learn the following sheet metal design techniques in Autodesk Fusion

Upsellit Privacy Policy. While the default K-Factor of 0. These features streamline the design process and enable designers to create accurate sheet metal components. Forms Maintenance: Feb This allows us to enhance your overall user experience. The software simplifies simulating sheet metal forming with an easy setup of loading conditions, contact conditions, fixes, displacement boundary conditions, and nonlinear material properties. AdWords Privacy Policy. Strictly necessary — required for our site to work and to provide services to you. Then you exit the sketch and create your sheet metal face and flanges. This information may be combined with data that StackAdapt has collected from you.

It is nonsense!

It is a pity, that now I can not express - I hurry up on job. But I will return - I will necessarily write that I think.