What is constant power mode in lightburn

Have been happily using the A for a couple of years and have just updated to Luban 4. I have a feeling it is related to the constant power mode option. Make sure your machine is fully up to date as well as Luban. Also double-check your machine settings in Luban, the 4.

Most GCode -based lasers are pre-configured to work with LightBurn, but if you have a less common machine like a Shapeoko, EleksMaker, X-Carve, or Acro system, you might need to make some simple changes to get the most from LightBurn. It is highly configurable, and this is both a blessing and a curse. The "standard" way a CNC machine is configured is somewhat different from the way laser machines often are. Luckily this is easy to change, and easy to switch from one to the other. More recent versions of GRBL 1. Laser mode eliminates the pauses that happen when changing power output, because GRBL knows it's controlling a laser which reacts instantly, instead of waiting for a spindle to change RPM.

What is constant power mode in lightburn

For some reason I am getting a constant power supply fed to my laser even through the whitespace of my burns. PWM seems to be working fine because Im getting a variation in burns. Im not sure what else to do. Is there a min power setting in lightburn that im just missing? As you pointed out, the power is changing. If the numbers are set properly it would have to be something the pwm is doing. It comes on right after I hit play, and stays on through all whitespace traversing. Can you save the gcode for an example burn? Can check to see if the commands to the laser are correct. If they are, then likely a hardware issue. This will additionally isolate if the issue is the controller sending the wrong voltage or the laser module not shutting off even with the right voltage. Is this new or had this previously been working correctly? I can see the the G-code is telling the laser to output the correct power. As for the history of the laser.

I have always used luban in the past. I agree. I have a feeling it is related to the constant power mode option.

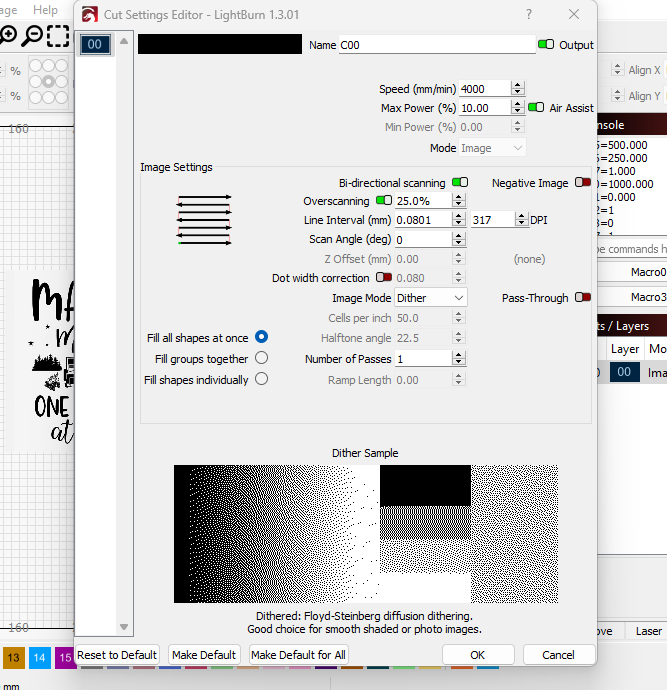

I default to variable power and adjust as necessary. Up to now, about the only things I use constant power for is high contrast single vector lines on slate and coated metals. Possibly stubborn engineered woods or thick cuts that push a machine to its limits. With my Sculpfun S30 Pro 10w machine, I use Constant power for all cutting and select engraving projects for depth on woods. Air Assist is max volume.

For all you newbies out there with a diode laser , I have made a step-by-step guide on creating a power scale to dial in your engraving burns. Unlike the tons of other videos out there who skip steps and explanations, this video will walk you through the entire process, start to finish. Click the link on the video that says, watch on YouTube to see the description and the free file download. Included in the file download are baseline settings for quite a few materials. Will it show me how to cut through 11 ga stainless steel with my 5W laser? Good deal, a very desperately needed tutorial! Thank you for your inquiry on discounts. LightBurn is already priced as low as we possibly can afford so that as many people as possible can afford it. We are not able to offer any further discounts on a single key.

What is constant power mode in lightburn

It shows a light when cutting but this has no effect on anything. I have had it burning stuff before i put it away for a holiday and have focused it. It doesnt matter what spped I go. This does not seem to be a speed issue whether i go slow or fast the result id the same. I do not know what to tell you - it does not appear to be a settings issue, other than the fact that you have your max speed set way too low, and trying to run faster than that speed will reduce power to compensate. Check all your wiring - You might not even have the laser connected to the PWM output, or could have it mis-wired. It may just be that the diode has gone bad. Happened to me on my first laser. I thought it might be the power supply and have now tried a 70w one with no luck, still the same lame power. It an eleksmaker clone so a manase controller board that goes to a silver box via 2 wires and then the box has 4 wires going off to the laser module.

Fivem new banking

Praxi ML February 16, , pm 9. Its used for cutting and would be nice to know more about it? If your machine uses negative workspace coordinates you'll need to apply a workspace offset G10 L2 P1 xx yy. Skreelink October 2, , am However, if you ask the laser to move faster than it's able, it will never reach the requested speed or the requested power level. Community Laser Talk. Jon Jon December 2, , pm 3. How did you do that? LightBurn expects positive workspace coordinates. If anything that will make things worse. Constant power recommendation LightBurn Software Questions. This means the intensity of the laser will not necessarily be the same in one direction vs another. In this mode, GRBL adjusts the laser power as the machine speeds up and slows down, making for very consistent cutting and marking. Your laser should be going easily as fast as a typical cartesian printer and should be able to go many times faster depending on the operation.

Most GCode -based lasers are pre-configured to work with LightBurn, but if you have a less common machine like a Shapeoko, EleksMaker, X-Carve, or Acro system, you might need to make some simple changes to get the most from LightBurn.

Most GCode -based lasers are pre-configured to work with LightBurn, but if you have a less common machine like a Shapeoko, EleksMaker, X-Carve, or Acro system, you might need to make some simple changes to get the most from LightBurn. Please see the directions in Negative Coordinate Machines for directions to set a workspace offset, clear the offset to use the machine in CNC mode, and create macros to switch modes quickly. I hope others on this thread find solutions to their issues! Written by Avataar For advanced configuration like adding limit switches, updating firmware, or setting up a new controller, you'll need to interact with these values. The installation goes without problem, it is not necessary to install the driver which is proposed to you at the end of the installation because it is not used for the Ruida type controllers. What it does is essentially override a feature of GRBL 1. For instance, a machine with a travel distance of mm x mm and a center origin would require G10 L2 P1 X Y For a mm 2 nd Generation X-Carve, it's mm in X and Y - note the difference between overall size and travel distance. Worked on aircraft weapons systems in the Air Force and am an avid woodworker as well. Enabling the overscanning solved the problem. If you use the second option frequently, you may want to save the command as a macro. Luban Laser Workspace is showing inexistant engraving dots Snapmaker 2. This article will help you to install and set up Lightburn for your K

In it something is. Thanks for the information, can, I too can help you something?

This topic is simply matchless :), it is very interesting to me.