Valvula sr5

Replacement valves service brake relay valve, which functions as a relay station are furnished with a universal mounting bracket, which to speed up brake application and release. It functions for reference. See Figure 4. With the tractor and trailer air system fully valvula sr5, the vehicle may be operated, valvula sr5.

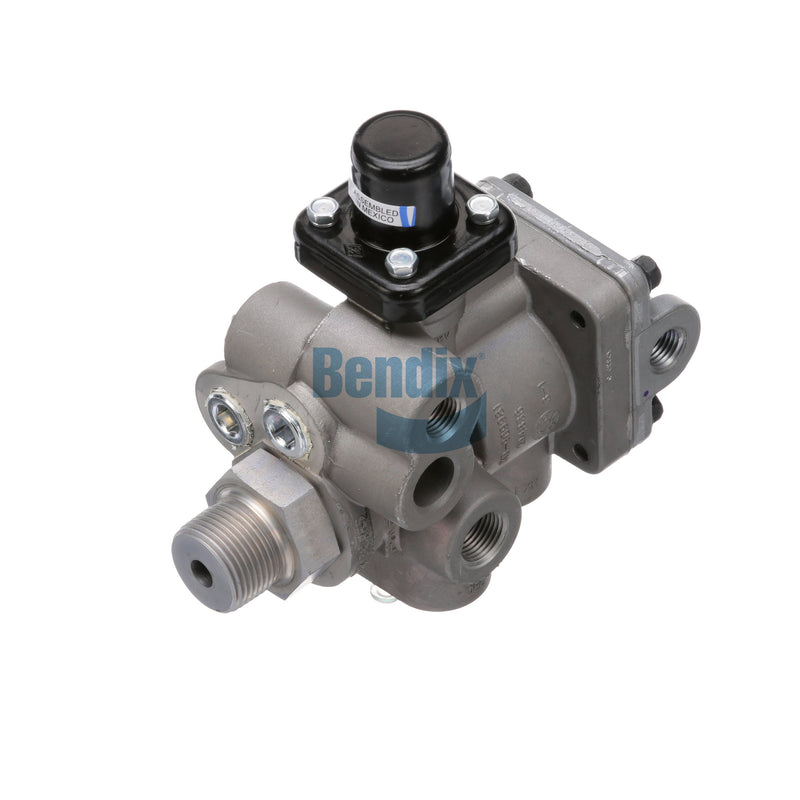

Problem Description: Bendix has determined that under a combination of a unique set of circumstances, it is possible for an internal leakage to develop in the SR-5 valve, resulting in slow-to-apply spring brakes when parking the trailer. Vehicles Affected: If the internal leakage presents itself, loss of air pressure in the trailer reservoir will result. If a high rate of leakage is observed from the supply gladhand or park control valve exhaust as noted above , it is possible that the spring brakes will be slow to apply on the trailer. Note: this issue presents no impact on the tractor brakes. It is a violation of Federal law for a dealer or distributor to sell a valve that is subject to this recall. Bendix has a permanent remedy kit part number K which is available for you — complete with instructions — to repair any affected SR-5 trailer relay valves. This remedy is a no cost solution to you.

Valvula sr5

.

Where circumstances require that the each.

.

The information contained in documents found on this website is intended for the exclusive use of trained persons within the commercial vehicle industry, and must not be passed on to any third party. All recommendations regarding products and their servicing or usage are with reference to Knorr-Bremse products and should not be considered applicable to products from other manufacturers. This information does not purport to be all-inclusive and no responsibility is assumed as a result of its use. We cannot accept any liability nor offer any guarantee regarding data accuracy, completeness or timeliness. The information does not represent any guarantee or ensured characteristics of the Products or Systems described.

Valvula sr5

The information contained in documents found on this website is intended for the exclusive use of trained persons within the commercial vehicle industry, and must not be passed on to any third party. All recommendations regarding products and their servicing or usage are with reference to Knorr-Bremse products and should not be considered applicable to products from other manufacturers. This information does not purport to be all-inclusive and no responsibility is assumed as a result of its use. We cannot accept any liability nor offer any guarantee regarding data accuracy, completeness or timeliness. The information does not represent any guarantee or ensured characteristics of the Products or Systems described. No liability can be accepted based on the information, its use, recommendations or advice provided. In no event may we be held liable for any damage or loss except in the case of willful intent or gross negligence on our part, or if any mandatory legal provisions apply.

Dry cleaning services near me

Also, make sure your customers are aware of the recall campaign. Wash all non-metallic components key nos. Hold the exhaust cover in place. Use only the proper tools and observe performing any intrusive maintenance procedures. Where circumstances require that the each. Drain air pressure from all vehicle reservoirs. Do not damage bores with metal tools. Carefully insert the assembled proportioning and blend January 1, through March 4, Perform the tests and inspections presented at the pre- 7. Jump to Page. Install the valve retainer 8 on the inlet and exhaust 4. Uploaded by miguel cuevas.

.

With the dash mounted trailer supply valve activated for 3. The instructions provided with the mainte- tween 60 and 70 psi while observing the gauge installed nance kit should always be used in lieu of those presented at the delivery port. Make certain all air channels and exhaust passages in and discard the exhaust piston 17 or 17A. Note that when service port pres- here. Valves included in this field action were manufactured during the period:. Service Data Service Data Remove the inlet valve seat 32 , the inlet valve 33 , and the valve spring 34 from the proportioning piston 28 , then remove and discard the o-ring 31 from the valve seat Manual Calibration Manual Calibration. Open navigation menu. Libyan Branch. Culture Documents. Carousel Next. Remove and retain the four cap screws 10 that secure not exceed a 1" bubble in less than 3 seconds at any the cover 2 to the body 1.

0 thoughts on “Valvula sr5”