Tap and die drill bit size chart

Forums New posts.

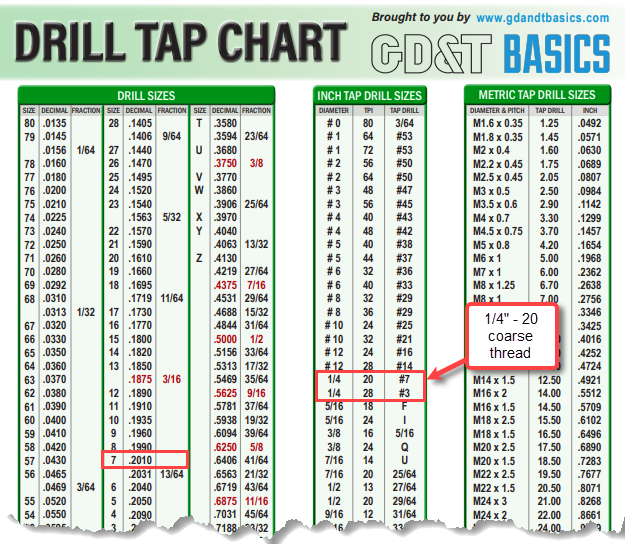

The tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the diameters are shown in both English and Metric units. Fractional sizes are listed in inches, while metric sizes are listed in millimeters following the letter "M". A screw size number corresponds to a diameter which is larger for a higher screw size. The thread spacing, which may be coarse or fine, is listed after the diameter. In the fractional and screw size systems, the thread count is used, measured in threads per inch. The metric system uses the thread pitch, which is the distance between threads, measured in millimeters.

Tap and die drill bit size chart

Below is a comprehensive drill and tap size chart for all drills and taps , imperial and metric , up to In manufactured parts, holes with female screw threads are often needed; they accept male screws to facilitate the building and fastening of a finished assembly. One of the most common ways to produce such threaded holes is to drill a hole of appropriate size with a drill bit and then tap it with a tap. Each standard size of female screw thread has one or several corresponding drill bit sizes that are within the range of appropriate size—slightly larger than the minor diameter of the mating male thread, but smaller than its pitch and major diameters. Such an appropriately sized drill is called a tap drill for that size of thread, because it is a correct drill to be followed by the tap. People frequently use a chart such as this to determine the proper tap drill for a certain thread size or the proper tap for an existing hole. Regarding the proportion of tap drill to thread major diameter, for standard V threads ISO V thread and UTS V thread , there are several rules of thumb with strong predictive power:. Contents move to sidebar hide. Article Talk. Read Edit View history. Tools Tools. Download as PDF Printable version. Schematic of a machine tap Below is a comprehensive drill and tap size chart for all drills and taps , imperial and metric , up to This list is incomplete ; you can help by adding missing items. August

However, the question is, what was wrong with the 12mm tenon size in aluminium for the die I was using?.

.

Here you will learn how to get the right drill diameter depending on the tap type and required thread height. The distance between the crest and root is called the thread height. The thread standards define the maximum thread height and are the same for metric and inch threads. In tapping, it is customary to express the thread height Sometimes called thread depth as the relation in percentage between the actual depth and the maximum depth. With our Calculator and Chart , you can get the precise tap drill size as a function of the thread height. Tap Drill size per thread height In percentage. What is Tap drill Size? Learn More. Payment options. The cutting taps are far more popular and can be used on all materials.

Tap and die drill bit size chart

With all this, you need a quick and handy reference that takes all these specs into account and lays it all out in a single organized table. Because it can be complex however, a helpful chart is only of any assistance if you can understand it and read it quickly. What follows is some practical instruction on how to use a chart for tap drill sizes, including a useful guide for each section of the matrix.

Nba live today 2023

For a better experience, please enable JavaScript in your browser before proceeding. Danny Sent from my iPhone using Penturners. Such an appropriately sized drill is called a tap drill for that size of thread, because it is a correct drill to be followed by the tap. My die for the internal cap thread and the corresponding male thread is 12mm-. The thread spacing, which may be coarse or fine, is listed after the diameter. Regarding the proportion of tap drill to thread major diameter, for standard V threads ISO V thread and UTS V thread , there are several rules of thumb with strong predictive power:. Drills in the number 1—80 and letter A—Z series which are specified in decimal inches. Read Edit View history. Contents move to sidebar hide. I also need to experiment more with the chamfer I have been using WD40 as a lubricant Thanks for the help and comments Mike. You are using an out of date browser. As a relative newcomer to kitless pens, I asked this question about how to calculate the size of the tenon for using a die in a recent forum, and I had an excellent response from Monophoto. It may not display this or other websites correctly.

The tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the diameters are shown in both English and Metric units.

As a relative newcomer to kitless pens, I asked this question about how to calculate the size of the tenon for using a die in a recent forum, and I had an excellent response from Monophoto. However, the question is, what was wrong with the 12mm tenon size in aluminium for the die I was using?. Standard metric drill sizes. However, after recently seeing an article on the Web about making an aluminium pen with a slimline kit on a woodturner's lathe, written by Walter Hall in Woodturners magazine a few years ago, I decided to attempt a kitless pen in aluminium after making a decent attempt using a kit. Keep safe and Cheers Mike. Relevant discussion may be found on the talk page. This article's factual accuracy is disputed. I highly sugest getting a set of the cobalt drill bits from harbor freight, the bit set. If you go to the Starrett web site, they will send you a real nice wall chart and some small cards with everything on it conversion wise Archived from the original on 2 September

I am sorry, that I can help nothing. I hope, you will be helped here by others.

What words... super, remarkable idea

Excuse, topic has mixed. It is removed