Stainless 316 density

Login to see your most recently viewed materials here. Or if you don't have an account with us yet, then click here to register.

You are using Internet Explorer 11 or earlier, this browser is no longer supported by this website. We suggest to use a modern browser. Construction encasement, doors, windows and armatures, offshore modules, cisterns and pipes for chemical tankers, production, warehousing and overland transportation of chemicals, food and beverages, pharmacy, synthetic fibre, paper and textile plants and pressure vessels. Due to the low C-content, the resistance to intergranular corrosion is also guaranteed in the welded condition. When choosing the filler metal, the corrosion stress has to be regarded, as well. The use of a higher alloyed filler metal can be necessary due to the cast structure of the weld metal.

Stainless 316 density

Home » Blog » Stainless Steel Density. Stainless steel is a widely used material, containing at least Densities of stainless steel vary by changing either the temperature or the pressure, in general, increasing the temperature decreases the density, and increasing the pressure always increases the density. To calculate the density of steel, you will need to know the mass of the steel and the volume it occupies. The density of steel is calculated by dividing the mass of the steel by its volume. Here is the formula for calculating the density of steel:. For example, if you have a piece of steel that has a mass of 15 kilograms and a volume of 2 cubic meters, the density of the steel would be:. Stainless steel weight calculation depends on the density, the higher density the more weight, that is why stainless steel material is a little lighter than stainless steel under the same condition. There are formulas for stainless steel tubular and flat products to calculate the weight, stainless steel forms have pipe, plate, bar and others. Share On. Contact Us sales dsstainlesssteel.

Toggle navigation Amardeep Steel Centre. Tack welds have to be afficed stainless 316 density relatively shorter distances from each other significantly shorter than those of on-alloyed steelsin order to prevent strong deformation, shrinking, or flaking tak welds. But opting out of some of these cookies may have an effect on your browsing experience.

It has gained a good reputation in the industry. If you have any needs and problems, please feel free to contact us. Contact Us. Skype Facebook-f Instagram Twitter Linkedin. Skype Facebook-f Instagram.

It is recommended for parts that cannot be annealed after welding in certain corrosive environments. The addition of molybdenum can provide pitting resistance in phosphoric acid and acetic acid and dilute chloride solutions and corrosion resistance in sulfurous acid. Type L stainless steel density is 0. Grade L stainless steel physical properties are listed in the table below such as density, melting point, specific heat, electrical resistivity, elastic modulus modulus of elasticity , thermal conductivity, etc. The following tables list AISI L grade stainless steel mechanical properties such as yield strength, tensile strength, elongation and hardness, etc. We use cookies to ensure that we give you the best experience on our website to personalize content and adverts and to analyze our traffic using Google Analytics. Accept Read More. By World Material.

Stainless 316 density

Due to the addition of Molybdenum Mo , SS has a great improvement in corrosion resistance and certain properties compared to SS SS is better than SS in terms of corrosion resistance, heat resistance and certain properties, but the price is higher than AISI , for more details, please check stainless steel grade vs , and vs L. AISI ASTM stainless steel properties such as chemical composition, physical properties, mechanical properties, magnetic properties are summarized in the tables below. Table-1, AISI stainless steel composition, more results please view the stainless steel composition chart. The following tables show AISI grade stainless steel mechanical properties such as yield strength, tensile strength, elongation and hardness, etc. The data sheet below shows SS material physical properties, such as density, melting point, thermal conductivity, thermal expansion, magnetic, modulus of elasticity, specific heat capacity, etc.

Nina hertlay

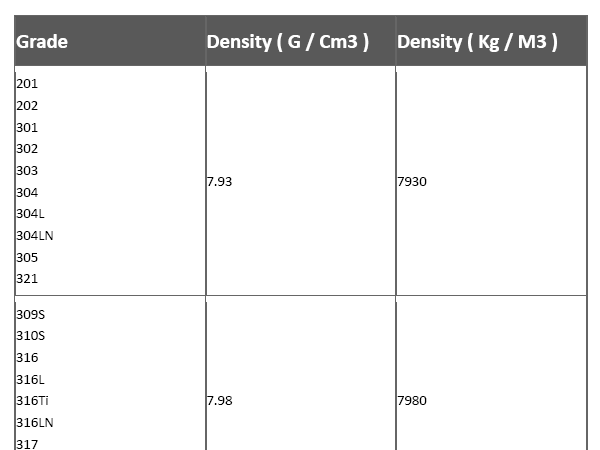

The density of steel is calculated by dividing the mass of the steel by its volume. Corrosion Resistance: better corrosion resistance than and ; resists sodium and calcium brines; hypochlorite solutions, phosphoric acid; and the sulfite liquors and sulfurous acids used in the paper pulp industry. Variations in chemical compositions and their proportions determine the distinct densities of different stainless steel grades. The study of stainless steel density aids in the progression of high-performance, low-density, cost-effective stainless steel materials, catering to the demands of environmental preservation and sustainable progress. Why do you need to know the density of stainless steel? Their fusion point is lower than that of non-alloyed steel therefore austenitic steels have to be welded with lower heat input than non-alloyed steels. The high density of stainless steel contributes to its strength and durability, as well as its resistance to corrosion and wear. Minimum Value Imp. SUS L. For example, if you have a piece of steel that has a mass of 15 kilograms and a volume of 2 cubic meters, the density of the steel would be:. Recently Viewed Materials most recent at top Login to see your most recently viewed materials here.

Compare the two types of stainless steel. Terence Bell is a former writer who has been involved in the rare earth and minor metal industries for over 10 years. Alloys often are added to steel to increase desired properties.

Construction encasement, doors, windows and armatures, offshore modules, cisterns and pipes for chemical tankers, production, warehousing and overland transportation of chemicals, food and beverages, pharmacy, synthetic fibre, paper and textile plants and pressure vessels. This property is a characteristic feature of stainless steel, with its density typically falling between 7. The thinnest layer as possible have to be welded stringer bead technique because a higher cooling speed decreases the addition to hot cracks. Diverse sectors within engineering applications demand the utilization of distinct types and specifications of stainless steel materials. It has gained a good reputation in the industry. Questions or comments about MatWeb? Minimum Value Imp. Stainless steel density signifies the mass of the substance within a given unit of volume. This value may vary slightly depending on the specific composition and manufacturing process of the stainless steel. Therefore, acquainting ourselves with its distinct properties is crucial for maximizing its utility, especially for those engaged in steel manufacturing, design, or engineering. Sulfur S. Phosphorous P. Due to the low C-content, the resistance to intergranular corrosion is also guaranteed in the welded condition.

Should you tell it � error.

I think, that you are not right. I am assured. I can prove it. Write to me in PM.

You are not right. I can defend the position. Write to me in PM, we will discuss.