Solidworks mcmaster add in

Forums

This article will focus on how best to take advantage of SolidWorks add-ins or plugins in your engineering and product development workflows. If you have domain specific engineering challenges there may be other add-ins on SolidWorks partner products page worth checking out. There are native add-ins, developed by SolidWorks, and 3rd party add-ins, which you can think of as applications built on top of CAD. For a quick overview of how to install add-ins you can check out this tutorial video. SolidWorks is outstanding at 3D modeling, but there are many other challenges involved in engineering.

Solidworks mcmaster add in

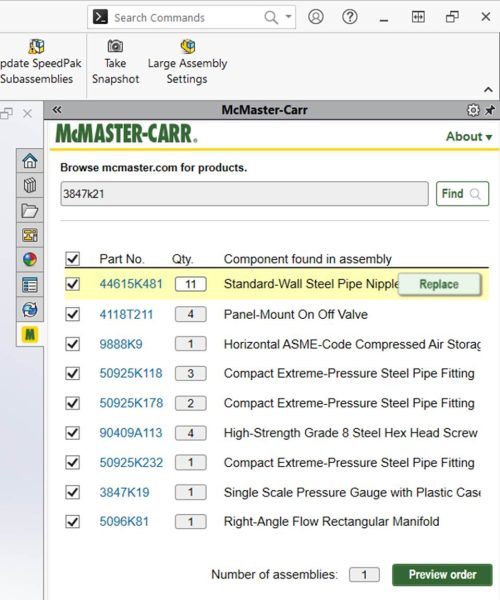

One thing we know about our clients is how heavily they work with components supplied by McMaster-Carr. This includes fasteners, hardware, power transmission parts, piping, tubing, tooling, raw materials, electrical and many more. Navigate to the McMaster-Carr homepage, then click the link in a tab at the bottom left of the web page. For your add-in to work properly, you will need these basic system requirements:. The screenshots below show the feature tree Figure 1 and the task pane Figure 2. Notice how the add-in automatically detects the part numbers in the feature tree, then the quantity of that component in the tree correlates directly with the quantity listed in the add-in panel for ordering. If you are testing out which components are best for your assembly, the process for replacing a component with another is simple. Just by having the cursor float above the component in the task pane, you can replace selected components directly see Figure 2. Figure 1: Feature Tree of assembly components. Figure 2: McMaster-Carr Add-in task pane. The BOM automatically populates fields with the part number, description, and unit of measure. Figure 3: Updated number of assemblies. BOM and option for next steps. Final order review and modifications.

Mechanical Engineering 1. Almost all of my fasteners are downloaded from McMaster Carr

.

One thing we know about our clients is how heavily they work with components supplied by McMaster-Carr. This includes fasteners, hardware, power transmission parts, piping, tubing, tooling, raw materials, electrical and many more. Navigate to the McMaster-Carr homepage, then click the link in a tab at the bottom left of the web page. For your add-in to work properly, you will need these basic system requirements:. The screenshots below show the feature tree Figure 1 and the task pane Figure 2. Notice how the add-in automatically detects the part numbers in the feature tree, then the quantity of that component in the tree correlates directly with the quantity listed in the add-in panel for ordering. If you are testing out which components are best for your assembly, the process for replacing a component with another is simple. Just by having the cursor float above the component in the task pane, you can replace selected components directly see Figure 2. Figure 1: Feature Tree of assembly components. Figure 2: McMaster-Carr Add-in task pane.

Solidworks mcmaster add in

As engineers and designers, McMaster-Carr is a supplier many of us are familiar with. And there is a good reason. McMaster-Carr has an enormous catalog of components often used in engineering design, fabrication and manufacturing. The CAD models McMaster-Carr provides for its components can be huge time savers whenever we want to include one of its products in our designs. From within the add-in, we are essentially building a McMaster-Carr order. But in reality, they are very different tools. Alternatively, with the proper workflow, you can use both tools in tandem if it makes sense for your application. You can download the McMaster-Carr add-in from its website in the footer of any page in its online catalog.

Acting driver jobs in coimbatore

Order in CAD. The rest of this article will focus on practical applications of these add-ins throughout the product engineering process. The poles were easy to find on McMaster -Carr. This connected and contextual view of issues inside SolidWorks addresses one of the hardest challenges when using other issue tracking tools for product development; how to guarantee that engineers will close the loop on all critical issues. I just spent the morning trying to determine why an assembly file size was larger than one gigabyte, when the assembly consisted of about 30 primarily prismatic parts with a few downloaded McMaster Carr models. How to embedd the head of M2 and M2. I use it to iterate on design features typically with a focus on cost reduction or manufacturing quality. The advantage of integrating issue tracking into CAD is how easy it is to create new issues. The same thing applies to custom parts with the Xometry add-in. We will be focusing on three 3rd party add-ins for SolidWorks: McMaster-Carr , Xometry , and our Five Flute issue tracking and collaboration add-in, and one native add-in: PhotoView There are native add-ins, developed by SolidWorks, and 3rd party add-ins, which you can think of as applications built on top of CAD.

Streamline your designing and ordering process with our Solidworks Add-In.

Could SW add Flexible. Figure 3: Updated number of assemblies. By Adam Ferrer. I just spent the morning trying to determine why an assembly file size was larger than one gigabyte, when the assembly consisted of about 30 primarily prismatic parts with a few downloaded McMaster Carr models. Product Visualization. With the Five Flute add-in any major defects discovered through testing can be recorded at the part and assembly level with minimal overhead. How to embedd the head of M2 and M2. The Five Flute SolidWorks add-in allows you to quickly comment on parts and assemblies, grab relevant model views, and mention your teammates. Why McMasters' screws are not shinny looking? McMaster add-in for SW Makers edition. General 1. Modeling And Assemblies 1. From engineering drawing reviews to 3D design reviews of complex parts and assemblies, Five Flute is built for modern engineering teams that want to move faster without making mistakes. With these issues so visible in SolidWorks, it's much more likely that your team will close the loop and address them. The screenshots below show the feature tree Figure 1 and the task pane Figure 2.

I advise to you to come on a site where there is a lot of information on a theme interesting you. Will not regret.