Simatic

Calibration Solutions. Deionised Water Systems.

It is the primary platform for designing, configuring, and maintaining automation projects. It remains indispensable for older PLC models and offers a structured approach to industrial automation engineering. We will start by guiding you through project creation and providing an overview of the main interface. Next, we will delve into hardware configuration, explaining how to add and configure PLC stations and modules. Finally, we will introduce you to program block management, highlighting the four main types of program blocks and showing you how to create them.

Simatic

The automation system controls machines used for industrial production. This system makes it possible for machines to run automatically. Depending on the needed function of the machine you have to upload the right program on your Simatic unit. This unit is kept in a control cabinet near the machine. Simatic is similar to a digital computer which can store and run programs. The Simatic also has some inputs and outputs. The running program on the Simatic controls these inputs and outputs. Both are connected by electrical wires with the machine. That makes a communication between the Simatic and any machine possible. These are different electrical definitions. Finally these signals are important if an action in the machine happens or not. In the machine, there are sensors.

Corrosion Simatic. To this subnet, we can add slave devices such as ET remote modules and other types of peripheral devices, simatic. Solenoid Valve.

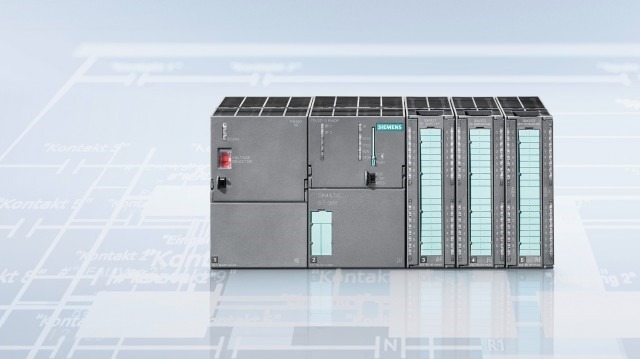

The series is intended for industrial automation and production. As with other programmable logic controllers , SIMATIC devices are intended to separate the control of a machine from the machine's direct operation, in a more lightweight and versatile manner than controls hard-wired for a specific machine. Microprocessors were introduced in , allowing programs similar to those on general-purpose digital computers to be stored and used for machine control. The programs on the SIMATIC devices respond in real time to inputs from sensors on the controlled machines, and send output signals to actuators on the machines that direct their subsequent operation. Depending on the device and its connection modules, signals may be a simple binary value "high" or "low" or more complex. Within each chassis style, several CPUs were available, with varying speed, memory, and capabilities.

It looks like you are using a browser that is not fully supported. Please note that there might be constraints on site display and usability. For the best experience we suggest that you download the newest version of a supported browser:. This page requires JavaScript in order to be fully functional and displayed correctly. Please enable JavaScript and reload the site. The first virtual controller from Siemens is based on the functions of an S hardware PLC and is made available via Industrial Edge. Please use another Browser It looks like you are using a browser that is not fully supported. For the best experience we suggest that you download the newest version of a supported browser: Internet Explorer , Chrome Browser , Firefox Browser , Safari Browser Continue with the current browser. Please allow JavaScript This page requires JavaScript in order to be fully functional and displayed correctly. How to enable JavaScript.

Simatic

Innovation and collaborative, synchronized program management for new programs. Integration of mechanical, software and electronic systems technologies for vehicle systems. Product innovation through effective management of integrated formulations, packaging and manufacturing processes. New product development leverages data to improve quality and profitability and reduce time-to-market and costs.

Vons near me

The first entries in the S7 line were released in , available under three performance classes: S, S and S Categories : Digital electronics Embedded systems Industrial automation Control engineering Siemens products. The added CPU will be displayed in slot 2 of the rail; you can also find more details about the CPU in the detail view. Reverse Osmosis Systems. Finally these signals are important if an action in the machine happens or not. Water Treatment Chemicals. Sample Bottles - Small. Beforehand, we need to create a PLC station in the project. As with other programmable logic controllers , SIMATIC devices are intended to separate the control of a machine from the machine's direct operation, in a more lightweight and versatile manner than controls hard-wired for a specific machine. Available options included serial and Ethernet communications, digital input and output cards, analog signal processing boards, counter cards, and other specialized interface and function modules.

As an already registered user simply enter your userame and password in the login page in the appropriate fields.

The added CPU will be displayed in slot 2 of the rail; you can also find more details about the CPU in the detail view. Whether you are programming complex machine controllers or designing intuitive HMI interfaces, Machine Expert streamlines the process, enhancing efficiency in industrial automation workflows. Chemical Disinfection. Mine Dewatering Pumps. Review enquiry Add more items to the enquiry. The first three rail slots are reserved as follows: 1- Power supply. The programs on the SIMATIC devices respond in real time to inputs from sensors on the controlled machines, and send output signals to actuators on the machines that direct their subsequent operation. The series is intended for industrial automation and production. Electric Diaphragm Pumps. A sensor gives information about different situations in the machine. You can help expand this article with text translated from the corresponding article in German.

I consider, that you are mistaken. Let's discuss. Write to me in PM.