Seal weld symbol

What is a Seal Weld? A seal weld refers to a specific type of weld that is applied to create a seal or closure between two surfaces, seal weld symbol.

We have received your request and will respond promptly. Log In. Thank you for helping keep Eng-Tips Forums free from inappropriate posts. The Eng-Tips staff will check this out and take appropriate action. Click Here to join Eng-Tips and talk with other members! Already a Member?

Seal weld symbol

Powered by mwForum 2. Not logged in American Welding Society Forum. By zieglejo Date Could someone help me settle a "discussion" between my engineer and welders? The problem: a joint between two plates at approximately 90 degrees to each other; the inside corners of the plates are touching corner-to-corner; no overlap ; the weld takes place from the outside with complete penetration. The two questions are: Is it proper to put a "melt-thru" symbol on a fillet weld? Is this actually considered a fillet weld, or is it a 90 degree included angle, single-v-groove weld? I looked through AWS A2. Any comentary will be greatly appreciated. Thank you. By Date

This lends credibility to their response and the opinions they express. I am having an issue with about a mile of fence we built for a customer.

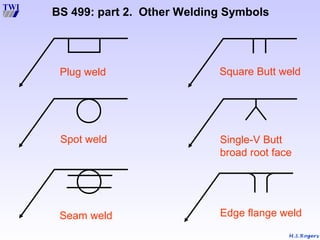

Published on: 21 July Welding symbols are a set of standardized symbols used on welding blueprints or drawings to communicate how welds should be performed. They provide important information such as the type of weld, size, length, and other details necessary to complete the weld correctly. The main function of a seal weld can be to confine a fluid, which could be in a gaseous or liquid state. In sectors like mechanical and structural engineering, seal welds are commonly utilized not necessarily to keep a fluid from leaking out of a container, but rather to stop a fluid from infiltrating an area where it might cause damage, typically through corrosion. Seal welding is a process used to prevent leakage in a joint by welding a leak proof weld.

Home » Welders. Engineers and welders use weld symbols during construction. During metal joining processes, weld symbols are meant to indicate different parts of the process. These symbols are usually found in fabrication and engineering drawings. A weld symbol would differentiate between two sides of a joint using arrows and the spaces on top and under the reference line. You would create the weld based on the instructions under the reference line.

Seal weld symbol

Excellent Detailed Insights. Have you ever paused to wonder how massive storage tanks, high-pressure pipelines, and various industrial equipment stay leak-free, even under the harshest conditions? Seal welding plays a pivotal role in various industries, ensuring that connections remain air-tight and water-tight. By design, these welds resist leakages, preventing fluids be it gaseous or liquid from penetrating a cavity. The goal of seal welding is straightforward: create a hermetic or pressure-tight seal between two components or surfaces. Think of a pressure vessel — a leak could not only cause loss of material but potentially lead to catastrophic failures. These standards ensure that welds truly prevent any leakage, guaranteeing a hermetic or pressure-tight seal. Read Also : What is an Inverter Welder? It begins with ensuring a tight fit-up, having minimal gaps, and aligning everything perfectly.

Flights to new orleans louisiana

This drawing is excerpted from D1. I guess I have to jump in on this discussion. Seal welds are not guaranteed any strength. However, in doing so, I am forced to "learn" and rethink my position on the subject. Respectfully, Jeffrey. Yet, experience has shown that you are lucky to achieve penetration to the root. In this case the fillet weld has melt-thru, which in itself is not cause to reject the weld. But as you said in your first post,,,,, Maybe it's just a poor detail. Promoting, selling, recruiting, coursework and thesis posting is forbidden. But, since the poster stated that "the weld takes place from the outside with complete penetration" The symbol call out should be in my opinion a Vee groove rather than a fillet Melt thru may be indicated on the opposit side of the vee groove symbol What you describe is pretty common for autogenous GTAW on sheet. I am leaving for CO early in the morning. Got a quick one there, and I might just see about driving my old rig up there and catch a couple of quick welding gigs while I am there as well. In the above described situation, what would, iyo, be the best way to prepare that outside joint?

Material Welding. Seal welds is a type of weld joint placement that provides an air-tight and water-tight connection for pipes or any other weld configuration. Seal welds are a specific type of welding commonly used in a variety of industries, such as construction, manufacturing and automotive repair.

The joint detail should be easy to weld, i. The sketch attached shows just two of the options that could have been used and differentiates between the fillet weld on the joint versus the groove in the joint. Seal welds are often employed in the production of products which require a high level of sealing integrity and strength. The person reading the report immediately knows the work was rejected for cause, not due to personal bias. I don't believe anyone would object to calling the weld depicted a fillet weld based on the definition above, i. Are you an Engineering professional? But then considering the definition of a fillet weld "A weld between two members at approximately 90 degrees to one another", it does not make reference to which side of said joint is to be welded. Sandeep Kumar. When ever I report a non-conformance or reject a fabricator's work, I try reference the standard code , section, and clause that has been violated or is the basis of the rejection. Powered by mwForum 2.

Quite right! It is excellent idea. I support you.

The matchless theme, very much is pleasant to me :)