R410a operating pressure

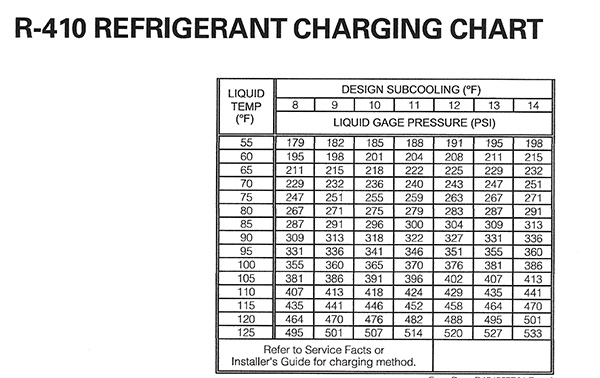

Updated: Nov 20, R410a operating pressure is important to know the range of these pressures in order to understand why and how charging and recovery are performed. Remember that temperature will affect the pressure of a refrigerant. If the air temperature surrounding the refrigerant increases, the refrigerant will absorb that heat and increase in temperature.

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account. Note that passwords are case-sensitive. Remember Me? Results 1 to 11 of

R410a operating pressure

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant. Some manufacturers, contractors, and industry organizations seem to be "almost" requiring those who do business with them or work for them to become certified in the safe and proper use of RA. Although this particular certification is voluntary, failure to certify may cost contractors and technicians some lost business. The purpose of this article is to provide a brief overview of the essentials of working with RA. Those who have the time and opportunity to attend a RA certification seminar are encouraged to do so. Most of the seminars and published materials on this topic not only cover the specific differences necessary to the safe and proper handling of A, but they also review information that technicians should already know anyway. In this article only the essential differences between R usage and RA usage will be discussed. However, if a technician is going to take the voluntary A safety exam, he or she will be required to answer a number of general questions common to the function, operation, and servicing of all mechanical compression cooling systems. Every technician is expected to have a good solid knowledge of the complete mechanical cycle, superheat, subcooling, latent heats, and the major components of a system. A review of the basic system, accessories, and even global warming and ozone depletion is essential. Refrigerant A was developed to replace refrigerant 22 because R is being phased out due to its ozone depletion potential. RA has no ozone depletion potential but does have a higher global warming potential. However, according to experts, the global warming potential using RA should be lower overall because of its higher efficiency, enabling reduced power plant emissions.

It is even more important to use suitable brazing materials on RA systems. One is because the liquid line is small in r410a operating pressure volume so there is a better chance of weighing the full amount of liquid refrigerant needed into the unit. Be very careful here; it would be very easy and convenient to use whatever recovery cylinder was handy rather than the correct cylinder.

.

In full disclosure, we may earn money from companies like Amazon mentioned in this post if you make a purchase through our links. Thanks in advance for the support! Mini-splits air conditioners depend on the refrigerant for their proper functioning. The refrigerant passes through copper tubing between the indoor unit and the outdoor unit. As it passes through a mini-split system, it moves heat from one side of the air conditioning system to the other.

R410a operating pressure

Updated: Nov 20, It is important to know the range of these pressures in order to understand why and how charging and recovery are performed. Remember that temperature will affect the pressure of a refrigerant. If the air temperature surrounding the refrigerant increases, the refrigerant will absorb that heat and increase in temperature.

Concacaf gold cup standings

The unit is microchannel, and it also has a TXV. Do they tend to run high on the high side because of more restriction, etc.? User Name:. Using the previous examples comparing the operating pressures of an R system to an RA system, the R system would have a compression ratio of 3. Therefore, only a compressor designed for A should be used with A. That is, they absorb moisture quickly and hold the moisture they absorb. This will stop the refrigerant from flowing from the bottle into the system. Such should not be the practice on RA systems. Thanks for your response Jlcook A micro channel coil is very easy to over charge. This would allow for slow charging while the system is off. Under identical operating conditions, the discharge temperature on a A system may actually be lower than on an R system. Originally Posted by dooner Please read this

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant.

Is this comment offensive? Posting Quick Reply - Please Wait. Results 1 to 11 of The compression ratio is affected by the pressure differential between the high and low sides of the system, not how high both pressures are. This refrigerant and its systems are here to stay. The scroll compressor has the advantage over the reciprocating compressor when comparing volumetric efficiencies and internal heat transfer losses between the suction and discharge ports. Remember that temperature will affect the pressure of a refrigerant. The high pressure switch is rated for psi so I diagnosed a bad high pressure switch. Therefore, only use filter-driers rated for use with RA. It is even more important to use suitable brazing materials on RA systems. Errors The following errors occurred with your submission.

Excuse, that I can not participate now in discussion - it is very occupied. But I will be released - I will necessarily write that I think on this question.

Excuse for that I interfere � But this theme is very close to me. Is ready to help.