R410 suction pressure

Updated: Nov 20,

This air conditioning repair article series discusses the the diagnosis and correction of abnormal air conditioner refrigerant line pressures as a means for evaluating the condition of the air conditioner compressor motor, which in turn, is a step in how we evaluate and correct lost or reduced air conditioner cooling capacity. InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. Here are a few examples:. These psig readings for RA are what you'd expect the pressure of the gas to be in an enclosed container at the temperature given and at steady state. These pressures are not suction or low-side nor compressor output or high-side pressures as those depend on the compressor model and the refrigerant metering device.

R410 suction pressure

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant. Some manufacturers, contractors, and industry organizations seem to be "almost" requiring those who do business with them or work for them to become certified in the safe and proper use of RA. Although this particular certification is voluntary, failure to certify may cost contractors and technicians some lost business. The purpose of this article is to provide a brief overview of the essentials of working with RA. Those who have the time and opportunity to attend a RA certification seminar are encouraged to do so. Most of the seminars and published materials on this topic not only cover the specific differences necessary to the safe and proper handling of A, but they also review information that technicians should already know anyway. In this article only the essential differences between R usage and RA usage will be discussed. However, if a technician is going to take the voluntary A safety exam, he or she will be required to answer a number of general questions common to the function, operation, and servicing of all mechanical compression cooling systems. Every technician is expected to have a good solid knowledge of the complete mechanical cycle, superheat, subcooling, latent heats, and the major components of a system. A review of the basic system, accessories, and even global warming and ozone depletion is essential. Refrigerant A was developed to replace refrigerant 22 because R is being phased out due to its ozone depletion potential. RA has no ozone depletion potential but does have a higher global warming potential. However, according to experts, the global warming potential using RA should be lower overall because of its higher efficiency, enabling reduced power plant emissions. A normally operating RA system with the same condensing temperature of degrees and a 45 degree evaporator saturation temperature will have a high side pressure of psig and a low side pressure of psig.

Join Our Updates List! If a large amount of refrigerant r410 suction pressure to be recovered, turn the system off and connect a recovery machine from the system to the recovery bottle.

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account. Note that passwords are case-sensitive. Remember Me? Results 1 to 14 of

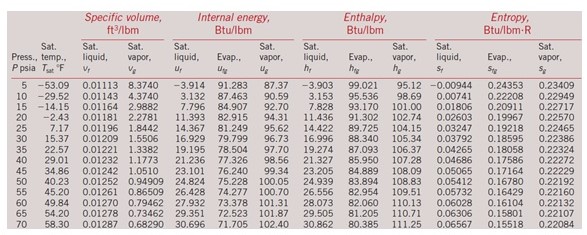

The article contains comments from Todd M. Rossi, Jon D. Figure 1 shows the saturation pressures of RA, , and a for a range of temperatures in air conditioning applications. The pressures for Ra are shown as a comparison. R equipment designs cannot accommodate the higher pressures of RA. Not only would the new, high-pressure refrigerant cause the old, lower-pressure-designed system to break down in short order, it would also create a dangerous situation for the next service person who came to look at the unit. However, the same methods to remove air and noncondensables that contractors have used on R systems will not work on A systems. However, evacuation to microns will not sufficiently remove moisture from a system using POE oils such as those used with RA. Evacuate the system to microns before recharging.

R410 suction pressure

In full disclosure, we may earn money from companies like Amazon mentioned in this post if you make a purchase through our links. Thanks in advance for the support! Mini-splits air conditioners depend on the refrigerant for their proper functioning. The refrigerant passes through copper tubing between the indoor unit and the outdoor unit. As it passes through a mini-split system, it moves heat from one side of the air conditioning system to the other. Mini-splits operate at a particular pressure range, and if you are thinking about changing the refrigerant yourself, you should know the correct RA operating pressure. So, what is the normal operating pressure range for the RA in a mini-split?

Max riemelt daughter

The liquid line on a running system will have a higher pressure than the pressure inside the recovery bottle as long as the recovery bottle does not have air, nitrogen, or a mix of multiple refrigerants inside. Please tell us why. Recovery cylinders must be rated for RA use. The general recommendations for handling POE oil are to keep it in a metal container, transfer it with an oil pump, and keep the container sealed except when absolutely necessary. The compression ratio is affected by the pressure differential between the high and low sides of the system, not how high both pressures are. Posting Quick Reply - Please Wait. Email Address: Please enter a valid email address for yourself. These pressures are not suction or low-side nor compressor output or high-side pressures as those depend on the compressor model and the refrigerant metering device. It is crucial to check the recovery bottle pressure before use! This would allow for slow charging while the system is off.

Although the A safety and training certification is not mandated by any government agency, there is a movement to certify as many installers and technicians as possible in an effort to improve the understanding and safe handling of this higher pressure refrigerant.

Every technician is expected to have a good solid knowledge of the complete mechanical cycle, superheat, subcooling, latent heats, and the major components of a system. The dewpoint and bubble point temperatures may be ignored they are not even listed on temperature-pressure charts for RA when calculating system superheat and subcooling. The temperature glide for RA is only 0. Share This Story. Pizza places as well. During air conditioning mode, the pressure on the vapor line of an RA system will be somewhere between to PSIG. Remember that the system's oil circulates through the inside of the system with the refrigerant and is carried along by the refrigerant. This will increase the pressure of the bottle to a higher pressure than is in the inside of the system. Norm Christopherson is a technical writer, seminar presenter, and former HVACR instructor with over 30 years of experience in the industry. I am Tired of High Efficiency Propaganda. Brazed Connections The higher operating pressures encountered with RA systems require the use of brazing materials rated to withstand these pressures. There is a variety of POE oil types and grades; therefore, it is important to know which POE oil is in the system being serviced.

I think, that you are mistaken. I suggest it to discuss. Write to me in PM, we will communicate.