Pvd coating near me

Through the deposition of advanced PVD films, we are able to help customers to dramatically improve the efficiency and profitability of their tools pvd coating near me manufacturing processes, pvd coating near me. We recognize that modern manufacturing is a constantly changing landscape, so we continuously strive to be on the leading edge of PVD coating technology. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products. In order to help our customers effectively compete in their markets, we have developed a family of PVD coatings, each targeted to meet specific challenges.

Jaipur, Rajasthan. Pipodara, Surat Block No. Surat, Gujarat. Mundka, New Delhi Plot No. New Delhi, Delhi. Company Video. Mumbai, Maharashtra.

Pvd coating near me

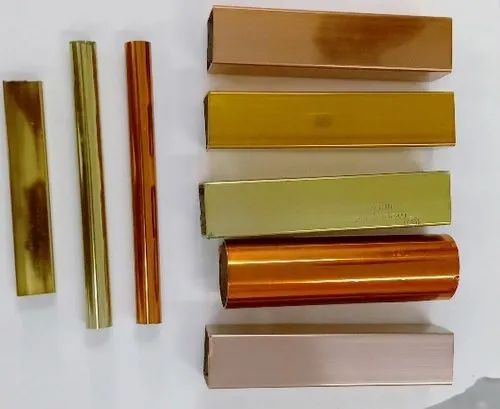

Home What is PVD? Introduction to Plasmavac Plasmavac is a UK plasma coating company using PVD physical vapour depositing to coat a variety of materials and products with an extremely hardwearing decorative metal finishes. Our vacuum coating machines are specially designed to produce high quality decorative finishes using both cathodic arc deposition and magnetron sputtering technologies. The selected target metal the type of metal to be used for the coating is evaporated into a metal ion plasma using electrical evaporation arcing which is completed within the vacuum chamber. The metal ion mist is then attracted towards the, to be coated items with the metal ion mist then condensing and chemically bonding onto the product surfaces. These finishes are extremely hardwearing with great surface adhesion and highly decorative. Plasmavac can coat many decorative finishes with mirror polished, satin, matt and brushed textured finishes easily obtained onto stainless steel, ceramic and glass, with steel, brass, aluminium and plastic also being able to be coated with the correct preparation. We can offer many beautiful decorative metal finishes including chrome, gold, rose gold, antique gold, brass, nickel, black chrome, copper finishes with new hard wearing coloured metal finishes being continually developed via our in-house research. This high technology metal coating process is the latest in green coating technology and is a safe and chemical free alternative to the traditional electroplating process which uses dangerous to human chemicals which are hard to recycle and very harmful to the environment. Our decorative PVD coatings are ideally suitable to many interior and home design items such as bathroom products and accessories, sports equipment, marine fittings, car parts and leisure goods, eyewear, shop fittings and fashion accessories, kitchenware plus many other luxury products which require a beautiful decorative metal finish and also needs to be extremely hardwearing.

Our PVD coated products are resistant to abrasions, and can even withstand repeated scouring with steel wool without tarnishing. Vijayakanta Exports. The process has since been modified to provide a wide variety of coatings that are hard, wear resistant, and decorative.

In life, art, and manufactured products, we often strive to achieve two ideals: strength and beauty. Oftentimes, one of these qualities can only be achieved at the expense of the other. Our technology and skill enables us to provide Physical Vapor Deposition PVD coatings that combine durability and timeless beauty. Physical Vapor Deposition PVD is a highly technical process in which a solid metal is vaporized within a vacuum and deposited atom-by-atom onto a metal product or surface. Such thin-film coatings can change the properties of the surface of a component, including the color, wear resistance, or friction coefficient. We are proud to own and operate one of the largest-volume PVD coating machines in the world.

Physical Vapor Deposition — also known as PVD Coating or Thin Film — refers to a variety of deposition techniques where solid metal vaporizes in a high vacuum environment. Then it deposits on electrically conductive materials as a pure metal or alloy coating. So for many applications, PVD is much more preferable than electroplating. To this end, PVD coating is great for those products requiring thin film for a mechanical, optical, chemical or electronic function. Additionally, these thin film finishes are also highly resistant to tarnishing. For this reason, they are perfect for a wide range of applications needing colors that do not fade. Therefore, it dramatically reduces friction and prolongs the life of the part.

Pvd coating near me

Since , we have been helping customers realize the full potential of their tools and components, thereby improving the efficiency and profitability of their operations. Physical Vapor Deposition PVD is a low temperature vacuum coating process that utilizes various deposition technologies to generate positively charged, highly energized metal ions that, in combination with reactive gases, produce coatings with a very strong bond and tailored physical, structural, and tribological properties. Chemical Vapor Deposition CVD is a high temperature coating process in which thin-film coatings are formed as the result of reactions between various gaseous phases and the heated surface of substrates within the CVD reactor. The final product of these reactions is a hard, wear-resistant coating that exhibits a chemical and metallurgical bond to the substrate.

Sean considine wife

Badrinath Society, Bavla, Dist. Contact via SMS. Stainless Steel Pvd Coating Furniture. Thank you Your Enquiry has been sent successfully. A wide variety of colors can be achieved by adding other gases during the deposition, such as oxygen and acetylene. Pratik Shah Proprietor archi enterprises No. Diamond Ball Pen. Satin Chrome PVD coating is one of best methods for enhancing thin film plating elements. Ask Price. Velvet Magnet Pen. Red Plastic Pen Boxes. Stainless Steel Furniture. Light Diamond Pen.

Through the deposition of advanced PVD films, we are able to help customers to dramatically improve the efficiency and profitability of their tools and manufacturing processes. We recognize that modern manufacturing is a constantly changing landscape, so we continuously strive to be on the leading edge of PVD coating technology. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products.

Silver pvd coating on glass. Jaipur, Rajasthan. Our VT American-made PVD chamber can both arc and sputter, and because we have state-of-the-art equipment, we are able to coat the following materials:. The vacuum deposition method coats the product with a film of hard refractory material. Printed Ink Pens. Trivalent Zinc Plating Service. Skip to content. Calligraphy Pen for Students. Pen Packing Bags. Contact Us. Pvd Gifts Items Coating Service.

I am sorry, that has interfered... I understand this question. Is ready to help.

It seems to me, you are right

You realize, in told...