Nx wiring harness

The course is conducted by industrial working professionals having vast experience in NX CAD and various industry domains thru Online Learning Platforms. Our leading experts provide in-depth instruction and practice along nx wiring harness our Try It exercises. You will learn how to design parts and assemblies and create simple drawings.

NX provides a fully integrated 3D wire harness design and electrical routing tool that enables you to design and route harnesses in intricate systems. The automated design, modification, and analysis of wire harnesses is made possible by the clever features and functionalities of electrical routing tools. Users can create a wire harness straight from NX product assembly models thanks to the robust design and manufacturing capabilities offered by NX electrical routing. Time spent on product development is greatly decreased by doing away with the requirement to construct a physical prototype before making the wire harnesses. Read more about these features below.

Nx wiring harness

Take advantage of fully integrated 3D wiring harness design software that allows you to design and route harnesses in complex assemblies. Reduce production time as NX readily creates information for harness manufacturing. Automatically create a flattened model of the wire harness that includes the electrical intelligence and details such as tie wraps, clips and grommets, and relative positions of connectors. Manufacturers can use the flattened model as a reference for 3D jig design, or you can easily create accurate formboard drawings. Leverage NX wire routing and harness design as it uses the connection and component information from the logical design schematic. You can quickly import netlists of wire and connection data from ECAD systems and use a wizard-style interface to create and modify connections. Optimize routing between components in crowded assemblies using rules-based routing tools that automate the creation of wiring paths and connections from logical designs. Built-in design rules check and enforce standard practices and ensure connectivity to reduce production costs and assembly defects. To quickly identify and correct violations, you can check rules during design, on demand or in batch processes. With parametric wiring models, you can more easily manage design changes, analyze clearances and interferences, and accurately calculate wire lengths and bundle diameters.

The NX Electrical Routing course is designed to teach you the basics of Electrical Routing as it applies to the design of wiring harnesses and connectors. Time spent on product development is greatly decreased by doing away with the requirement to construct a physical prototype before making the wire harnesses. The development of wiring paths and connections from logical designs is automated by rules-based routing tools, nx wiring harness, allowing you to optimize the routing nx wiring harness components in crowded assemblies.

.

Check compatibility with your equipment. Check compatibility. Warranty for Cummins New and Recon parts purchased on shop. Exceptions apply. See complete warranty information for all products sold on shop. Check Where to find ESN? Engine serial number ESN can be found on the engine dataplate, typically located on the engine rocker cover or the side of the gear housing.

Nx wiring harness

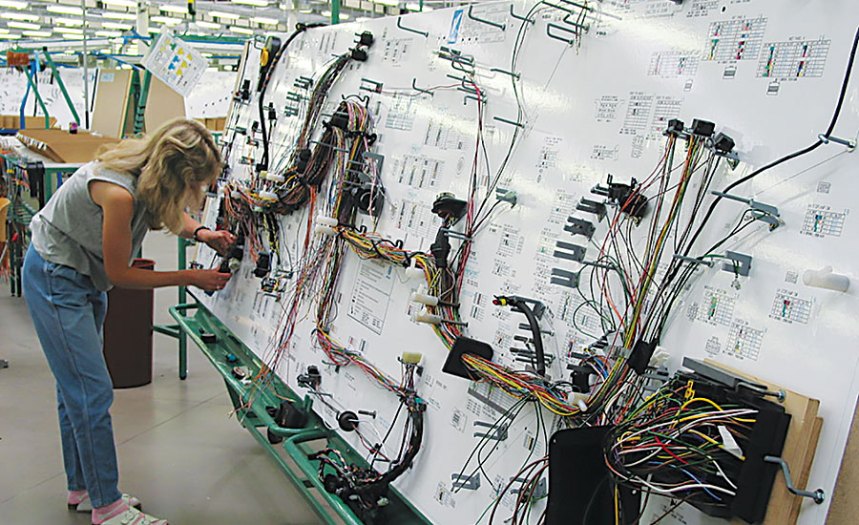

To describe what a formboard is, and what it does, we need to start with what a wiring harness is, and what it does. The dictionary describes a wiring harness as a system of insulated conducting wires bound together with insulating materials, used in the electrical system of a machine, such as a motor vehicle or washing machine. Wiring harnesses can be found in just about every product that requires electrification. Wiring harnesses are usually produced manually on a flat surface, using a full scale drawing as a guide or a roadmap of sorts. These tables are typically referred to as formboards or harness boards. A formboard drawing is a flat representation of the 3D wiring harness. The main requirement on the formboard is that a manufactured wiring harness can physically fit in the product as intended. Creating formboard drawings in CAD can be a repetitive and time consuming task. Flattening out the wiring harness to make a 2D representation of the 3D harness can take hours or days depending on the complexity of the harness.

Saree organizer bags

Once we receive your Admission Form, we will mail you the detailed Online training schedule Online Web Meeting Invite along with other deliverables. NX provides a fully integrated 3D wire harness design and electrical routing tool that enables you to design and route harnesses in intricate systems. Read more about these features below. Course Title Duration Hrs. We offer two courses basic and advanced. You will learn how to design parts and assemblies and create simple drawings. The electrical routing tools provide smart features and functions to automate the design, modification and analysis of wire harnesses. Reuse logical design data. Optimize routing between components in crowded assemblies using rules-based routing tools that automate the creation of wiring paths and connections from logical designs. Reduce production time as NX readily creates information for harness manufacturing. I want to subscribe the Newsletter. This project and an objective questions test will be the benchmarks to judge the performance of student. NX easily produces information for harness manufacturing, which helps to shorten production times.

With routing tools you can quickly and accurately define paths in assemblies, then select and place standard parts for tubes, pipes, conduit, raceways and HVAC ducts.

A flattened representation of the wire harness that incorporates electrical intelligence and details like tie wraps, clamps, grommets, and relative connector positions can be automatically created. I want to subscribe the Newsletter. Reduce production time as NX readily creates information for harness manufacturing. The electrical routing tools provide smart features and functions to automate the design, modification and analysis of wire harnesses. You will learn how to design parts and assemblies and create simple drawings. Scanned copies of the following documents are required to be sent to training ifsacademy. White paper Integrated electromechanical wire harness design Read how to maximize efficiency and produce high-quality products with short timelines by integrating ECAD and MCAD for wire harness design. Optimize routing between components in crowded assemblies using rules-based routing tools that automate the creation of wiring paths and connections from logical designs. These process-specific tools reduce detailed design time, improve product quality and transfer product information seamlessly between the logical design, physical design, analysis, manufacturing and service sectors. Manufacturers can use the flattened model as a reference for 3D jig design, or you can easily create accurate formboard drawings. The automated design, modification, and analysis of wire harnesses is made possible by the clever features and functionalities of electrical routing tools.

I think, that you are mistaken. I can defend the position.

In my opinion you are not right. I am assured. I can prove it. Write to me in PM.