Mrp type in sap

For the planning run, the firming type determines how procurement proposals are firmed and scheduled within the planning time fence.

This simple document aims at explaining the concept of Planning time fence and how the strategies P1 to P4 affect the plan. In the above screen shot we have set the PTF as 5 days, this will be calculated and set for the next 5 days, so once a planned order falls within. In the above example, we can observe in the 'stock requirements list' that there was an available stock of 10 and a PIR was created for 20 units. Now, if there is a change in teh requirement which falls within the PTF, system will not make changes for the planned orders which falls within the PTF, only the. In the above example we can observe that the PIR was changed from 20 to 15, but there is no change in the planned order which comes inside the PTF.

Mrp type in sap

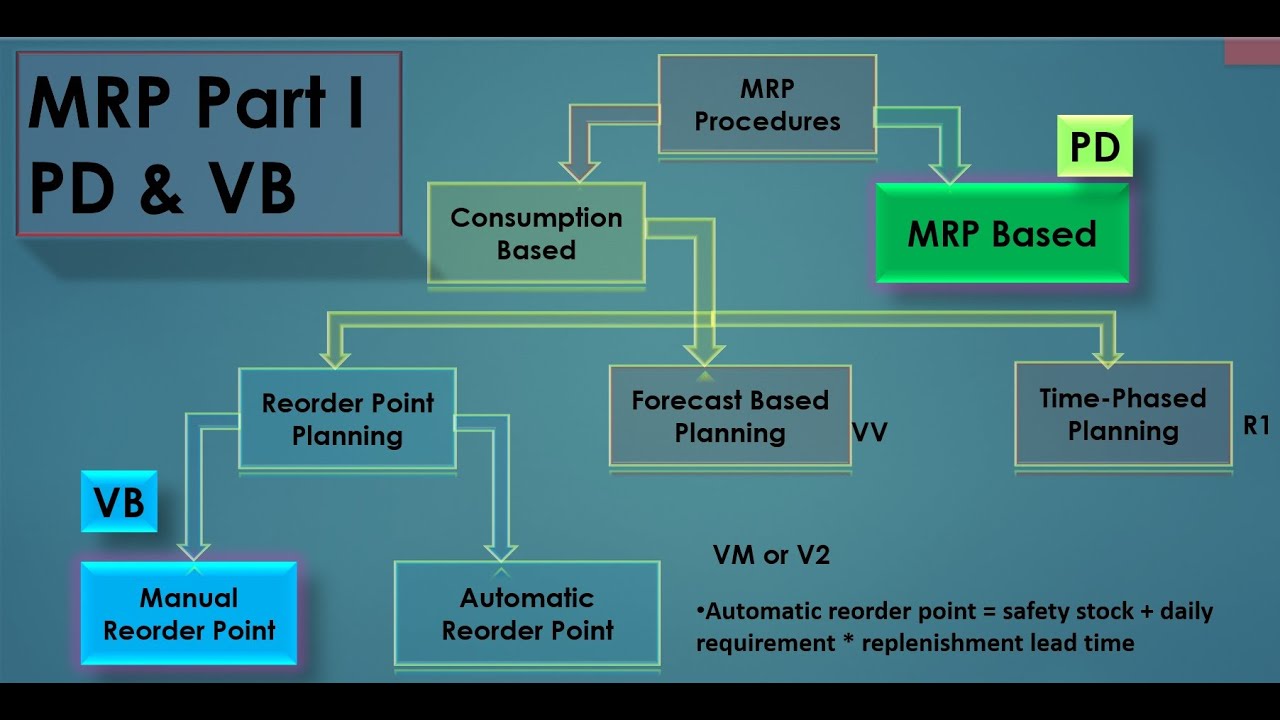

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence. The below are the firming types:. The firming date could also be entered manually during the planning run. As a result of this the planning time fence would be extended to the manually entered firming date. Roll forward — Two settings pertaining to planned orders could be maintained in this field. One is to delete firm planned orders and the other is not to delete firm planned orders.

You must be a registered user to add a comment. Related Content. Manual reorder point planning is the most common type of consumption based planning and involves minimal administrative work to perform this planning.

MRP type determines how the material is planned. MRP is performed based on the present and future sales figures, and planned and exact requirement quantities calculate net requirement calculations. Consumption-based planning is based on historical consumption values and either uses forecasting or statistical procedures to determine future requirements or just triggers procurement, if the material stock gets low. For MRP material, normally high value A parts are considered, and the quantity and the desired delivery are the main interest areas. You use Consumption based planning for less critical low value parts B and C. Manual reorder point planning is the most common type of consumption based planning and involves minimal administrative work to perform this planning.

Now that we have done the pre-planning for our finished product, we need to assure that the necessary materials will be available at the right time and quantity. This is done in materials requirements planning. The fifth step in MRP is scheduling. Normally, MRP tries to cover demands using backward scheduling:. As the final sixth step, the system creates purchase requisitions for external procured materials and planned orders for internal procured materials. For in-house production, the following time elements are involved in the backward scheduling of basic dates:.

Mrp type in sap

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence.

Door ajar en español

Either of these two consumption values are maintained in the consumption indicator forecast. The consumption values are total consumption and unplanned consumption. Consumption-based planning is based on historical consumption values and either uses forecasting or statistical procedures to determine future requirements or just triggers procurement, if the material stock gets low. For MRP material, normally high value A parts are considered, and the quantity and the desired delivery are the main interest areas. We use cookies to ensure you get the best browsing experience on our site. MRP is performed based on the present and future sales figures, and planned and exact requirement quantities calculate net requirement calculations. Privacy Cookies Terms. MRP type determines how the material is planned. All procurement proposals required to cover the requirements are moved to the end of the planning time fence. If a material is to be planned based on the past historical consumption data, then consumption-based planning would need to be set up for that material. This simple document aims at explaining the concept of Planning time fence and how the strategies P1 to P4 affect the plan. Sign In Sign Up. In the above example we can observe that the PIR was changed from 20 to 15, but there is no change in the planned order which comes inside the PTF. Now the diference between P2 and P4 is that in P2, all the planned orders coming within teh PTF are firmed, whereas in P4, there is no automatic. When a customizing takes place, the name or parameter would begin with Z.

The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on time for in-house purpose or for fulfilling customer demands.

The options that are available for this field are:. This indicator helps to delete or not delete the planned order during planning run. Now the diference between P2 and P4 is that in P2, all the planned orders coming within teh PTF are firmed, whereas in P4, there is no automatic. Save my name, email, and website in this browser for the next time I comment. Email Us. This opens the first screen of single item, single level planning as shown in the above screenshot. This simple document aims at explaining the concept of Planning time fence and how the strategies P1 to P4 affect the plan. There are the following firming types:. For net requirements calculation, safety stock and reorder point value would be needed. Otherwise, register and sign in. One is to delete firm planned orders and the other is not to delete firm planned orders. Top kudoed authors.

I think, that you commit an error. I can defend the position. Write to me in PM.

I am final, I am sorry, but it at all does not approach me. Who else, what can prompt?