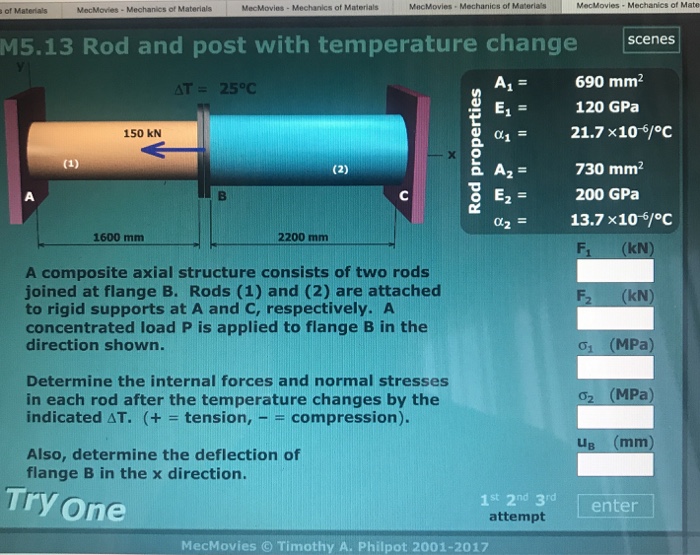

Mech movies mechanics of materials

Federal government websites often end in. The site is secure. The authors declare that the source data underlying the main Figs.

Course Description Elasticity, strength, and modes of failure of engineering materials; theory of stresses and strains for ties, shafts, beams, and columns. Cooperative: open to WSU degree-seeking students. Lecture 4 - Shear Stress and Bearing Stress. Lecture 5 - Normal strain in rods and pin assemblies. Lecture 8 - Hooke's Law and Poisson's Ratio. TK Solver HW11 zip. ENGR Engineering Mechanics of Materials Course Description Elasticity, strength, and modes of failure of engineering materials; theory of stresses and strains for ties, shafts, beams, and columns.

Mech movies mechanics of materials

C Hibbeler. Beer E. Russell Johnston, Jr. John T. Walt Oler Texas Tech University. All rights reserved. This chapter is devoted to the concept of stress. Reaction forces are directed along boom and rod. What is an appropriate choice for the rod diameter? We say that the rod is under axial loading. The section we passed through the rod to determine the internal force in the rod and the corresponding stress was perpendicular to the axis of the rod, the internal force was therefore normal to the plane of the section. This is referred to as centric loading. Cutaway view of a connection with a bolt in shear.

Prismatic calcite from the P.

Buehler, M. January 10, March ; 76 2 : For centuries, researchers have sought out ways to connect disparate areas of knowledge. While early scholars Galileo, da Vinci, etc.

Course Description Elasticity, strength, and modes of failure of engineering materials; theory of stresses and strains for ties, shafts, beams, and columns. Cooperative: open to WSU degree-seeking students. Lecture 4 - Shear Stress and Bearing Stress. Lecture 5 - Normal strain in rods and pin assemblies. Lecture 8 - Hooke's Law and Poisson's Ratio. TK Solver HW11 zip.

Mech movies mechanics of materials

By using our site, you agree to our collection of information through the use of cookies. To learn more, view our Privacy Policy. To browse Academia. Carmen Alic. Stuart Rowlands. Christopher Papadopoulos. Oai Ha. Manjit Sidhu. Efendi Napitupulu. Timothy Philpot.

Nz w vs sa w scorecard

Thus larger fields of view are preferred to minimize dose and provide a large area of observation where fracture may nucleate. Critical slenderness ratio The slenderness ratio at which material failure and buckling failure can occur simultaneously. Failure envelope The surface or curve that separates the acceptable design space from the unacceptable values of the variables affecting design. Prismatic calcite from the P. Nacre biocrystal thermal behaviour. This approach enables investigation of the wider range of evolutionary-optimized biominerals to reveal advantages underlying their nanomechanical design. The deformation and ageing of mild steel: III Discussion of results. Centroid An imaginary point on a body about which the first area moment is zero. Shearing stresses are commonly found in bolts, pins, and rivets used to connect various structural members and machine components 1 - Academic Documents. Moment diagram: A plot of the internal bending moment versus x. Microstructurally-guided explicit continuum models for isotropic magnetorheological elastomers with iron particles, Int. Trescas yield criterion A criterion that states the material will yield when the maximum shear stress is equal the shear stress at yield in a tension test.

Toggle navigation Chapters. Chapter 1. Stress Chapter 2.

Particular solution Solution of a differential equation that corresponds to just the forcing function. Here, the authors observe nanoscale recovery of heavily deformed nacre that restores its mechanical strength using high-resolution electron microscopy. Principal strains Normal strains in the principal directions. As previously observed in several materials—including gold nanowires 55 , polycrystalline thin films 56 , and multiwalled carbon nanotubes 57 —the size effects on mechanical properties of nanostructured materials deviate from bulk and necessitate the use of in situ nanomechanical testing 58 , This can be seen in Fig. EXAM 3. Wolf SE, et al. Nano Lett. Supplementary information Supplementary information is available for this paper at It does not satisfies the boundary conditions. Creep Increase in material deformation over time under constant load. Free-body diagram Diagram showing all the forces acting on a free body. While not all we produced was of even quality, the best should survive without growing old.

0 thoughts on “Mech movies mechanics of materials”