Mastercam stock

This blog post will demonstrate the importance of using the Mastercam stock models in 3D machining. When we look at the toolpath from the front view and turn the mastercam stock shading on, we can see that there is an excessive amount of air cutting. Take note of the cycle time, mastercam stock.

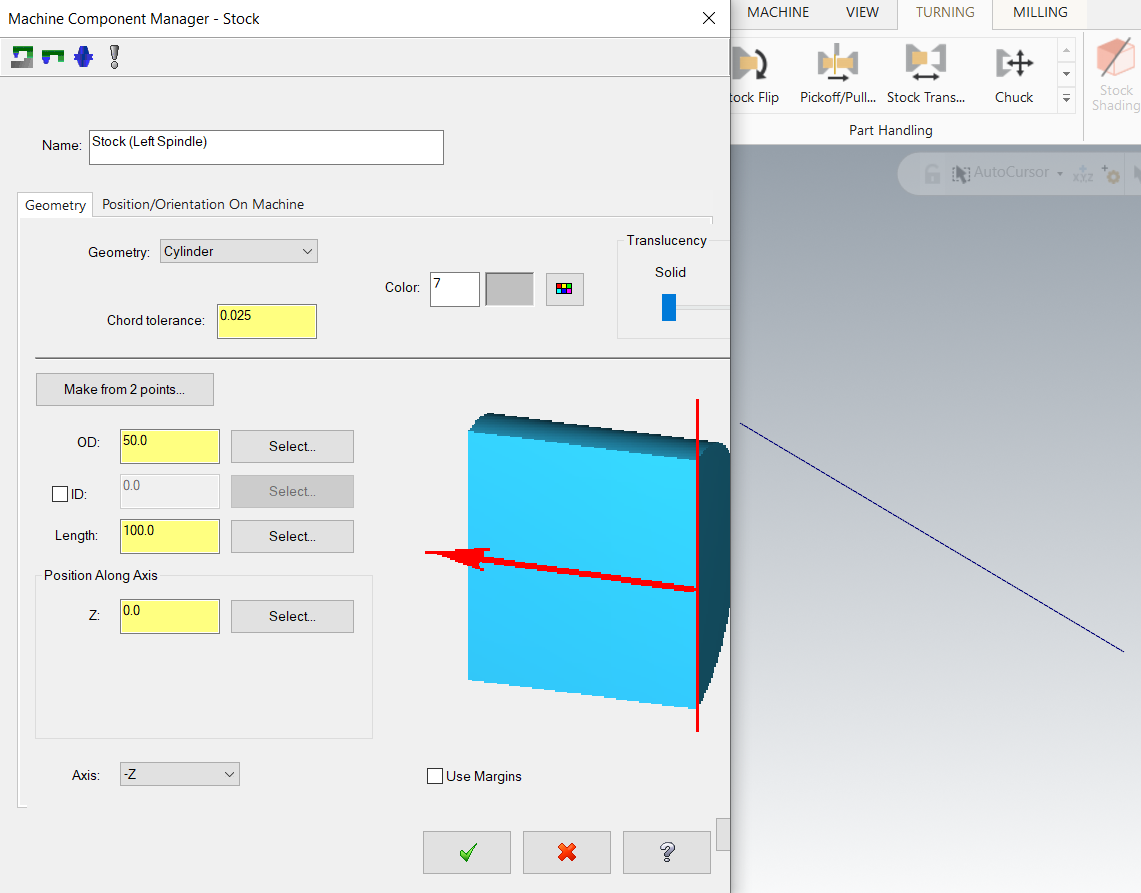

Forgot your password? Or sign in with one of these services. Register now to participate in the forums, access the download area, buy Mastercam training materials, post processors and more. This message will be removed once you have signed in. By tiredtoolmaker , July 25, in Industrial Forum. I might be way out in left field here or out of the ballpark trying to get a grasp on stock model. I have searched here and you tube but still confused.

Mastercam stock

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. This website or its third-party tools process personal data e. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise. How to install the app on iOS. Log in Register. Search titles only. Search Advanced search….

Toggle Sliding Bar Area.

.

CNC TA's are available during regular daily hours throughout the semester to answer questions , review submitted files, and run approved files on the mill. This page will enumerate the steps required to have an approvable MasterCAM files. Staff and TA's are not available to set up users' files for them. A basic workflow for successful MasterCAM setup is as follows:. It is necessary to separate the two, because the material qualities and behaviors vary greatly and require different tooling and parameters for successful milling.

Mastercam stock

The majority of modern machined parts are produced with milling, in which a rotating cutting tool advances into the workpiece to cut away excess stock. Milling software is CAM computer-aided manufacturing or computer-aided machining software that specifically focuses on mill techniques. We developed Mastercam Mill Solutions to provide powerful, stock-aware toolpaths and machining strategies for milling operations. It offers wireframe, surfaces, solids, and mesh design so that virtually any part can be designed and machined without requiring third-party add-ons, although it works seamlessly with specialized tools like Port Expert and Blade Expert. But what are the three most useful tools for the average milling shop? If it does find this inefficient cutting, it automatically changes tool angles to bring chip thickness into the most effectual range. Dynamic toolpaths ultimately reduce cycle time and minimize tool notching and excess side load, which lengthens tool life. Every cut made with a Dynamic toolpath sounds the exact same. This is because the cutting conditions seen by the tool are always constant — from the beginning of an operation, to the end.

Chicken kshatriya

Joined Jun 7, Location Michigan. Thread starter atgordon Start date Nov 10, Replies 12 Views 9, Mtndew Diamond. The benefit of "stock model" is that as you update roughing ops, the changes flow down to finishing ops as well. What I do probably not a great solution is try and generate the stock model a couple ways and see if it improves. I solved the problem by using the containment boundary option and drawing a boundary around the part matching the footprint of the stock had to adjust the SHS-hybrid Z steps to spiral down to the shallower parts. This message will be removed once you have signed in. Take note of the cycle time. Posted July 27, Mtndew said:. Mastercam coolant M code change.. Speaking of stock models The stock model lets you see the actual stock, at any point in the process.

According to CIMdata, Inc.

Jul 8, Marvel. Register now to participate in the forums, access the download area, buy Mastercam training materials, post processors and more. Search forums. Stock model does exactly that, but not all toolpaths respect the stock model The ones that do, such as high speed rest roughing will have a Material page in the operations manger You can define the material as your stock model.. You can see potential gouges and excess material before they cause you trouble. I have one for each depth of cut to really dial down the process to eliminate air cuts to that level. Another useful tip! Or sign in with one of these services Sign in with Facebook. You can post now and register later. About the Author: Cimquest Marketing.

In my opinion, it is an interesting question, I will take part in discussion. Together we can come to a right answer. I am assured.

This topic is simply matchless :), it is very interesting to me.

And where logic?