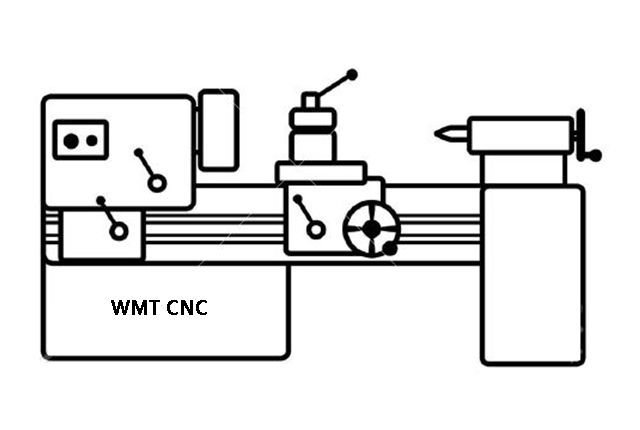

Lathe machine diagram easy

The Mechanical engineering stream has seen some tremendous machines invented and modified all these years.

In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing. In this article, I am going to discuss the Lathe machine in detail. Definition of Lathe Machine. Head Stock. Main Spindle.

Lathe machine diagram easy

Working Principle : The lathe is a machine tool which holds the workpiece between two rigid and strong supports called centers or in a chuck or face plate which revolves. The cutting tool is rigidly held and supported in a tool post which is fed against the revolving work. The normal cutting operations are performed with the cutting tool fed either parallel or at right angles to the axis of the work. The cutting tool may also be fed at an angle relative to the axis of work for machining tapers and angles. Construction : The main parts of the lathe are the bed, headstock, quick changing gear box, carriage and tailstock. Bed : The bed is a heavy, rugged casting in which are mounted the working parts of the lathe. It carries the headstock and tail stock for supporting the workpiece and provides a base for the movement of carriage assembly which carries the tool. Legs : The legs carry the entire load of machine and are firmly secured to floor by foundation bolts. Headstock : The headstock is clamped on the left hand side of the bed and it serves as housing for the driving pulleys, back gears, headstock spindle, live centre and the feed reverse gear. The headstock spindle is a hollow cylindrical shaft that provides a drive from the motor to work holding devices. Gear Box : The quick-change gear-box is placed below the headstock and contains a number of different sized gears. Carriage : The carriage is located between the headstock and tailstock and serves the purpose of supporting, guiding and feeding the tool against the job during operation. The main parts of carriage are:.

Specification of Lathe Machine We understood the types of lathe but in industries, the machines are specified based on certain criteria. CNC lathes provide the most accurate output and can be used in mass production, lathe machine diagram easy. With the knowledge of the components of the lathe machine, we will be able to understand the working principle of the lathe.

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles.

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles. One belongs to the headstock and the other belongs to the tailstock. So, each spindle is known as the headstock spindle and toolstock spindle. Chuck is a type of clamp that we use to hold the workpiece in radial symmetry. However, there are different mechanisms to clamp a workpiece in radial symmetry.

Lathe machine diagram easy

Last Updated on February 7, by Charles Wilson. Hence, before laying your hands on it, familiarizing yourself with the different parts of a lathe machine and its functions should be your first assignment. In this article, I will share with you the things I know about lathe operation, its main components, and the distinct parts of lathe machines depending on your tool. There are several parts in a lathe machine. It consists of main components that are similar to all types of lathe machines.

Budapest airbnb

Here is an image of an old lathe. With the knowledge of the components of the lathe machine, we will be able to understand the working principle of the lathe. Save my name, email, and website in this browser for the next time I comment. The grooving operation involves reducing the external diameter workpiece to a relatively small surface area. Definition of Lathe Machine. Tool Post The tool post is mounted on the compound rest and is used to carry cutting tool holders. The operation of creating a helical groove on a conical or cylindrical surface of the workpiece by feeding the tool longitudinally is called threading or thread cutting operation. The compound rest is fitted on the top of cross slide and is used to support the tool post and the cutting tool. Fig 3: Working Principle of Lathe Machine The working principle involves rotating a workpiece against a fixed cutting tool. You may be wondering about the various parts of this ancient machine tool.

The Engineers Post. In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.

Key Type. Tool Post. The boring operation on lathe machine involves enlarging a hole previously drilled, sometimes to create circular interior grooves. Bcoz most of parts of machine are use to make on this machine….. Its a good fundamental to know about lathe machine thanks. Save my name, email, and website in this browser for the next time I comment. Its speed can fluctuate from extremely low to extremely high, up to rpm. Work Holding device and. In the s, servomechanisms were applied to the numerical control of lathes and other machine tools, which were frequently linked with computers to produce computerised numerical control CNC. A lathe machine is a machine tool that is used to remove unwanted material from a rotating workpiece in the form of chips. Sarbah Ismaila March 6, Keep me updated on your posts through my emali. Tapers and Taper Turning. External grooving. Special purpose lathe machine.

Bravo, this phrase has had just by the way

It is remarkable, a useful piece