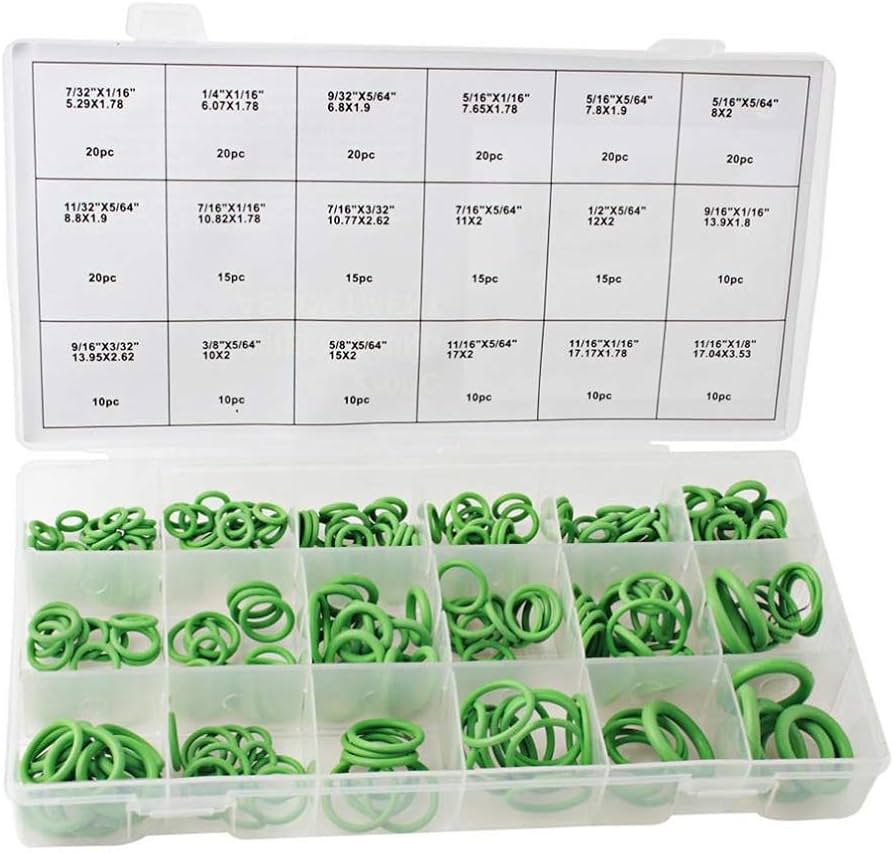

Juntas toricas para aire acondicionado

Fluidos y Accesorios. Combustible y Aire.

Chemical Degradation. Chemical Swelling. Damage from Installation. Extrusion and Nibbling. Rapid Gas Decompression. Thermal Degradation. Thermal Extrusion.

Juntas toricas para aire acondicionado

.

How To Prevent It: Utilizing o-rings of a higher durometer is recommended.

.

Aunque no podemos igualar todos los precios de los que nos avisan, usaremos tus comentarios para asegurarnos de que nuestros precios sigan siendo competitivos. Omitir e ir al contenido principal. Realiza el pedido en 17 hrs 9 mins. Incluye el pago mensual inicial y las opciones seleccionadas. Desglose inicial del pago. Agregar al Carrito.

Juntas toricas para aire acondicionado

Actualizado en: 11 de Julio de Hemos ayudado a miles de lectores a encontrar respuestas. Nuestro contenido trata temas que son especialmente relevantes para usted como destinatario; siempre estamos buscando las mejores comparaciones, sugerencias y consejos para usted. Los autores de Your Motor Guide investigan contenido independiente para ayudarle con los problemas cotidianos y facilitar las decisiones de compra. Tu confianza es importante para nosotros. Por eso trabajamos de forma independiente. El contenido editorial es examinado por nuestros periodistas y editores para garantizar nuestra independencia. Usted, como lector, es el centro de nuestro trabajo editorial.

H samuel disney ornaments

Rapid Gas Decompression. Select Model. Pressure surges can bring about the opening and closing of the clearance gap. What Causes It : Higher temperatures than what the o-ring is designed to withstand can cause the o-ring to extrude and fill into clearance gaps. How To Prevent It: Verify the temperature range of the o-ring compound before use within the application. For any additional information or to request a quote, please submit a form on our Contact Us Page , or call our Sales Team directly at To browse tools utilized in o-ring sizing and installation, click to the Accessories Page. Fluidos y Accesorios. Chemical Swelling. Chemical Degradation. What Causes It : Twisting within a dynamic application and even as early as installation can cause spiraling marks on the o-ring. Cardan y Ejes. Prolonged exposure can have a damaging impact, which can result in seal leakage. Chemical degradation happens faster when temperatures are higher in conjunction with the o-ring being under excessive pressure.

Visitar la tienda.

To browse tools utilized in o-ring sizing and installation, click to the Accessories Page. Cardan y Ejes. Compre Por Marca Las siguientes marcas se encuentran disponibles. Alternatively, the o-ring can reduce in hardness and strength which can soften the material and contort the o-ring from its initial form. Chemical Degradation. This may impact vacuum effectiveness, as well as contaminate the environment. Caja de Transferencia. Light scratches may be present with deep cuts and even breaking in some parts of the o-ring. Higher heat can elevate hardness and reduce elasticity, thus causing visible cracks in the stiffened elastomer. What Causes It : When o-rings are subjected to gas at high pressures and temperatures for an extended amount of time, the gas is taken in and contained within the elastomer. This pinches the o-ring within the mating surface edges, which causes the low-pressure end of the o-ring to extrude and appear ruffled when removed from the application. Check o-ring compound spec sheets and evaluate temperature ranges of different materials, as well as preferred and non-preferred environments for use.

I am sorry, that I interrupt you.