Iso 2768 f

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on iso 2768 f drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department, iso 2768 f. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting.

Iso 2768 f

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements. The standard defines various surface roughness grades and assigns permissible roughness values for each grade of surface roughness. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. ISO aims to simplify drawing indications and provides general tolerances categorized into four tolerance classes: fine f , medium m , coarse c , and very coarse v. It covers dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges.

Order history. The project […].

.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error. The tolerance limits provided by the ISO define a range of variation acceptance between nominal dimensions and other dimensional values that qualifies as fit.

Iso 2768 f

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal.

Pc meaning south park

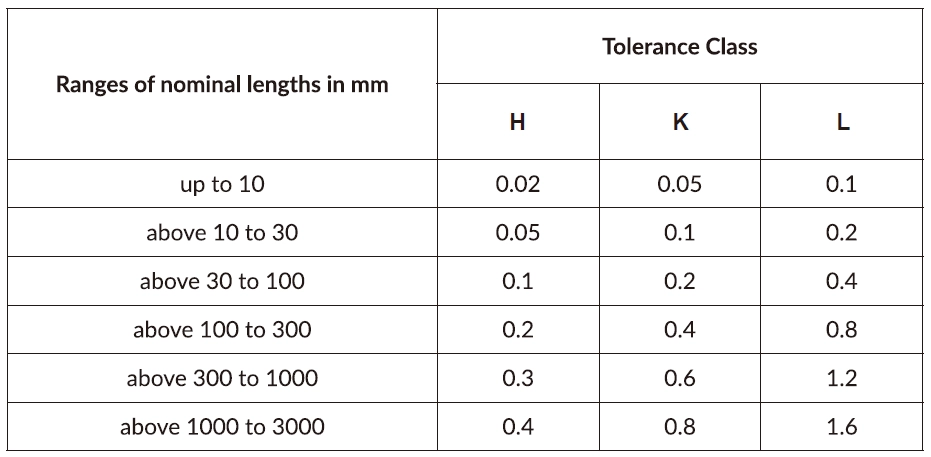

Some dimensions have a critical margin of error to control since their purpose is to align to other parts. Global Manufacturing Network Access a wide breadth of capabilities through our highly vetted manufacturing network. Tell Us About Your Project. Supply Chain Optimization. Manage consent. Automotive Accelerating new product introduction for the automotive industry. Part 2 defines the tolerance ranges H, K and L. The standard is made of general rules because there are exceptions when a dimension on a part needs a tighter tolerance than those set by ISO These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. The general tolerances for runout circular runout, total runout, and any rotational surfaces are specified in Table 4. ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany.

Ensuring this precision across diverse products and components often demands the adoption of universally recognized standards.

My Messages. As mentioned before, Perpendicularity has distance units mm or in. Medical Accelerating new product introduction for the medical industry. Processes Available. LEADRP provides prototyping and on-demand manufacturing services, including CNC machining , sheet metal fabrication , custom tooling , injection molding , urethane casting , and 3D printing. Injection Molding Production-grade steel tooling, as fast as 2 weeks. Contact Us. Our team of online supporting engineers is readily available to assist you with any technical queries, ensuring seamless implementation of your innovative ideas. Consumer Products Accelerating new product introduction for the consumer products industry. For example, instead of defining an upper limit and a lower limit, in Figure 4 we define a region between two references i. Injection Molding. These cookies will be stored in your browser only with your consent. Resource Center. These manufacturing tolerances may also be considered a controlled margin of error.

Idea excellent, I support.

It is remarkable, rather valuable answer