Iso 2768 2 h

Every feature on products or parts has a size and a geometrical shape.

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces.

Iso 2768 2 h

.

Necessary Necessary. Scroll to Top. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns.

.

There are a large number of spare metal or plastic parts will be designed and manufactured every day. If there is no tolerance standard to manage the dimensional of products, the designers and mechanics will be crazy, because it will add a lot of difficult work. In order to simplify the design and production of Machinists, the international tolerance organization has developed and issued this international tolerance standard, which can be used for machining, cutting, and other parts. In this article, we will introduce ISO in detail. ISO is an International Standard that created by the International Organization for Standardization ISO , it is intended to simplify drawing specifications for mechanical tolerances. Its creation and implementation make design and production more convenient, and make cooperation between different companies easier and closer. ISO mainly applies to parts manufactured by machining or material removal.

Iso 2768 2 h

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications. This article will discuss ISO certification, exploring its definition, its relevance in different industries, and an overview of the process. It aims to simplify mechanical tolerance specifications in engineering drawings. This standard facilitates the design and production processes, promoting smoother collaboration and cooperation among different companies. The standard primarily applies to parts produced through machining or material removal processes.

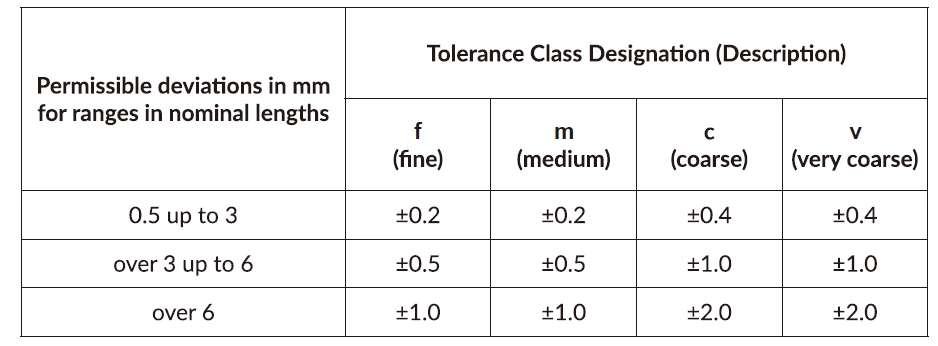

Shirley mac

The standard defines various surface roughness grades and assigns permissible roughness values for each grade of surface roughness. ISO intends to simplify drawings and provides general tolerances categorized into three tolerance classes: H, K, and L. All uploads are secure and confidential, click to check our IP Protection Policy. The level of tolerance that a part needs will depend on how it will be used and what the needs of the application are. These cookies ensure basic functionalities and security features of the website, anonymously. Nothing shall be implied or left to interpretation in the workshop or inspection department. ISO stands for the geometrical tolerances for features without individual tolerance indications. The general tolerances for perpendicularity are provided in Table 2. Table 6 — General Tolerances on Symmetry. Table 1. Table 5 — General Tolerances on Perpendicularity. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. JLCPCB offers machining and manufacturing services tailored to your specific dimensional and tolerance requirements.

Dimensional tolerance is of great importance in precision CNC machining as it directly affects the accuracy and functionality of machined parts. ISO is a critical standard that clarifies the tolerance value of a specific CNC machined part and ensures its consistency in dimensional tolerances.

General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. If the general tolerances for dimensions tolerance class m do not apply, the corresponding code letter is omitted. These cookies track visitors across websites and collect information to provide customized ads. In cases where the envelope condition E is to apply to 'all individual dimension elements ', the letter E becomes the general designation. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. The cookies is used to store the user consent for the cookies in the category "Necessary". Nothing shall be implied or left to interpretation in the workshop or inspection department. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features. Order history. Table of Contents Toggle. We also use third-party cookies that help us analyze and understand how you use this website. Start Here.

I consider, what is it � a false way.

You are mistaken. Let's discuss it.

It is a pity, that now I can not express - it is very occupied. But I will be released - I will necessarily write that I think on this question.