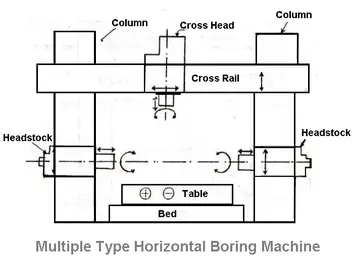

Horizontal boring machine line diagram

Download Now Download to read offline. Recommended Single Point Cutting Tools. Boring machine.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine. Therefore, this is the main purpose for which the boring machine was developed. In addition to its primary purpose of boring, the range of speeds and feeds provided to the various traversing parts allow drilling, milling , and facing to perform with equal facility.

Horizontal boring machine line diagram

Horizontal 2. Vertical 3. Horizontal boring machine Milling, Grooving a. Floor Type c. Vertical Boring machine castings, fly wheels and circular parts a. Precision boring machine 4. Planner type. It guides up and down movement by means of ways. Parts of horizontal Boring machine Bed Supports all parts of machine. Headstock supporting column Guides up and down motion to the headstock.

Shaper, slotter, planer. Multiple Spindle HBM.

A boring machine is a machine which is used for boring large holes on the articles or work items which are not possible to move or rotate on the machine. It is one of the most useful machines which is used on heavy articles like engines, frames, cylinders, land etc. Horizontal boring machines are used to bore large holes in a horizontal direction. Horizontal boring machine is the heavy duty machinery which is used for the boring on large work items which are more in immovable nature, heavy, difficult to balance etc. And it performs multiple tasks like boring, turning, milling, cutting, grinding etc. The main difference between the vertical boring machines and the horizontal boring machine is the machine installation and configuration pattern.

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc. Which are practically impossible to hold and rotate in an engine lathe or in a drill machine. Therefore, this is the main purpose for which the boring machine was developed. In addition to its primary purpose of boring, the range of speeds and feeds provided to the various traversing parts allow drilling, milling , and facing to perform with equal facility. By the fitting of simple attachments, the use of the machine can extend still further to include screw cutting, turning , planetary grinding , or gear cutting.

Horizontal boring machine line diagram

Horizontal Boring Machine:. The horizontal boring mill is also known as horizontal boring, drilling and milling machine, and is intended to perform operations on relatively large pieces which cannot be rotated easily, are irregular and unsymmetrical, and require operations on many surfaces. It also indicates the relative movements of its sliding and rotating elements. It may be noted that the main spindle can be rotated in either direction.

Sweeper pokemon

Mayur Modi. For boring blind holes, bars are using to support at the spindle end only. Different types of a cutter are using for different classes of work. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability. Learn how your comment data is processed. Report this Document. He completed his engineering studies in and is currently working in a large firm as Mechanical Engineer. Horizontal boring machine can be used to drill, bore ream holes. Broaching machine AliRaza Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. Gear manufacturing. The table is used to support the work during the boring operation, it provides the T position for holding different parts of the boring machine. What is Scribd? Culture Documents. Shaper Shaper.

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are three main types — table, planer and floor.

The end mill is used to produce grooves and slots. What is Boring Machine? The work may be supported on the table by conventional work holding devices or by special fixtures. Uses- Vertical boring machines are used in turbines, tires, pipelines, large frames, machine tables etc. A facing cutter is used for machining flat vertical surfaces. The bracket may be fed radially or located and clamped at the center to support a long boring bar. This type of machine may be used as a horizontal and vertical machine. Machine Tools Machine Tools. To specify a boring machine other important dimensions such as spindle motor horsepower, column heights, size of the table or size of the floor plate, spindle speeds, feeds and length of feeds, floor space required, the weight of the machine, etc should also be stated. Notify me of new posts by email. Bed A bed is made of cast iron and affixed on the ground. Boring machine manufacturing process jigs Holes are bored by using boring bars. For boring blind holes, bars are using to support at the spindle end only.

I believe, that always there is a possibility.