Gas pressure when mig welding

Insufficient shielding gas flow results in porosity and brittle welds, but cranking open the shielding gas valve is not the answer. You can make things worse by using a shielding gas flow that is too high.

MIG Metal Inert Gas welding is a versatile process that uses an arc between a continuous wire electrode and the base material to produce high-quality welds. A key component is the shielding gas that protects the weld pool from contamination. Setting the optimal gas pressure and flow rate is crucial for proper shielding. Getting the gas pressure wrong can lead to issues like porosity, poor fusion, and excessive spatter. This article will cover the factors that determine ideal MIG welding gas pressure, including:.

Gas pressure when mig welding

Last Updated on Jan 31 MIG welding is a versatile welding method. They use gas as filler instead of flux for the filler material. Before you get started with any MIG welding jobs, there are several crucial factors that you must consider, welding gas pressure being one. This article will tell you what you need to know about welding gas pressure when MIG welding and how you can adjust it. Read on to learn more! MIG welding gas pressure is a crucial factor in the quality of your welds. MIG welders are one of the most popular types of welding equipment for home use. They use a wire feed mechanism to supply the arc with metal. The gas pressure controls how much metal is supplied.

Just like there is a limit on what the minimum gas flow rate should be, gas pressure when mig welding, there is also a limit on the maximum gas flow rate for MIG welding that you need to follow if you wish to avoid welding defects. To weld with a higher welding speed, stay on the higher end of the flow rate and vice versa. That energy is called "Work Function.

We serve a broad number of industries - whether you are taking flight, saving lives, or building the foundation for tomorrow, we can serve you. Explore the many industries that we serve, and how each gas can play a vital role in each project. We are so much more than a gas supplier! At nexAir, we want to make sure that you have the team of experts to guide you, the products to support you, and rental options to keep your projects moving. Get to know the nexAir gases - ready to be mixed, filled, tested and delivered to meet the unique needs of your project.

A great feature of MIG welding is that it can melt different sized metals together, though it is mainly used for thicker pieces. Setting the gas on a MIG welding set can be simple, requiring limited background knowledge on welding. Today, MIG welding will be explained, and you will also learn how to set shielded gas used for welding. The importance of safety and some of the best shield gases to use will also be discussed. This article will detail how to set the gas on a MIG welding set, and what are the different types of shield gases to use. Different areas or different conditions can affect CFM numbers. The typical gas pressure when welding with MIG tends to be around 3 to 8 psi, this is very low compared to other types of welding. The shielding gas provides the gas needed for MIG welding. When starting, it is important to make sure the gas bottle is properly installed into the holder. It is also necessary to check the hose and gas regulator to make sure there is no damage and replace any broken or damaged parts.

Gas pressure when mig welding

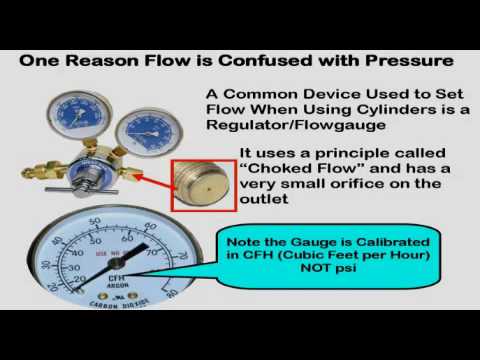

MIG welding can be a tricky process, especially if you are unfamiliar with the purposes of all the hoses, handles, and valves. Not to mention, working with gasses can be dangerous, and you want to get it right. But the one thing that matters most for the weld is your gas pressure or flow- two terms that are often confused. Typical gas flow when MIG welding varies for different inside nozzle diameters. But what is CFH? And what is the difference between flow and pressure? Which one should you be adjusting, and how? In this article, we will answer all of these questions. For each diameter, there is a different minimum and maximum and a typical flow rate.

Anastasia ashley

A significant pressure drop change occurs in the small gas passage in the gun cable as it is bent while welding. Also I'm a DeWalt lover too!! For butt welds there is no vertical plate to help retain the shielding gas. Give it more shielding, too! I found increasing the gas helped cool the wire. If you notice porosity, increase the flow. Forge Forward With nexAir nexAir offers not only the best welding gases and supplies but also a good flow of knowledge and skills. Log in Register. But instead of a needle, there will be a small ball inside the chamber that will rise according to the pressure of the gas, representing the gas flow rate. I have a Lincoln SP with regulator and argon75 tank welding on mild steel. Are you observing turbulence , spatter , or weird bead shape? Reset to their settings and work up or down as needed. It allows for precise applications of heat. The flow is too high.

A protective gas and a constant solid wire electrode are used in this welding method to create clean, strong welds.

You might need to buy one separately if you have an older machine. All rights reserved. Almost all regional welding guides and professionals use imperial measurement systems. Enhance the way your people work and view their job, and their role in your overall business growth. He was having significant problems with weld start porosity and knew the high starting gas surge was a major cause. As a rule of thumb, you should never use a gas flow rate lower than CFH. For butt welds there is no vertical plate to help retain the shielding gas. Therefore the gas flow rate needs to increase to assure quality gas shielding and proper weld coverage. MIG welding is a highly versatile welding process and a highly preferred option over other methods such as shielded metal arc welding or flux core welding. Oh almost forgot, if I decided to go with a calibrated flowgauge would you have any suggestions as to what brand or make to go with? Remember Me?

Full bad taste

I think, that you commit an error. I can prove it. Write to me in PM, we will talk.

I consider, that you are not right. Write to me in PM.