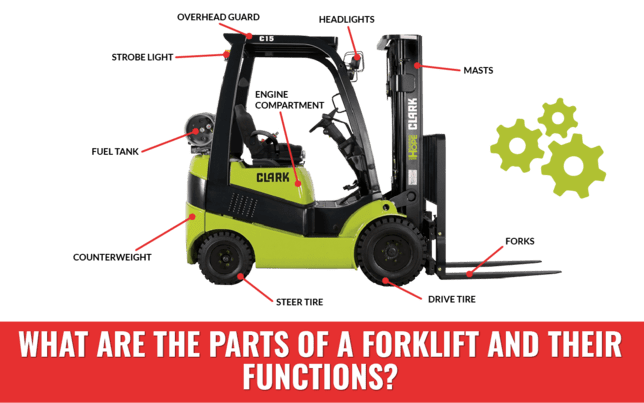

Forklift parts diagram

For this guide we are focusing on counterbalance forklift parts. In many operations, forklift parts diagram, a counterbalance forklift is usually the most adler дзен piece of support equipment in use. They are the forklift parts diagram of many operations and are called upon to work in a variety of environments including temperature extremes, harsh weather, difficult terrain and an extraordinary amount of weight and pressure due to the loads they carry.

The forklift is an industrial truck for lifting and transporting a load over a short distance. It serves the needs of the various warehouses and large facilities. In the 20th century, most companies started manufacturing. Nowadays, most warehouses use them. Due to that, extra time for loading and lifting material reduces and increases the work speed. Parts of a forklift are made of high-strength material as it deals with the heavy load. It operates by the engine or battery and uses the counterweight to balance the lifting load.

Forklift parts diagram

Learn about the different terminology and the various parts of a forklift truck. Use our forklift diagram for reference. Forklifts have many moving parts and pieces that allow the forklift to operate properly. Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job. Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. The forklift mast is the raised vertical support that allows loads to be raised and lowered. Forklift masts come with various sections that elevate or lower the forklift carriage along with the forks. These include:. This will allow you to select a forklift that is designed to fulfill the specific needs of your applications. For more information on forklift masts, read our article Forklift Mast Types. The forklift lift cylinder powers the vertical movement of the mast, or the raising or lowering of the forklift carriage and the forks. The lift cylinder is generally hydraulically powered and is a single-acting hydraulic cylinder, meaning it pushes in one direction. Similar to the lift cylinder, the tilt cylinder controls movement for operation purposes. The key difference is that the tilt cylinder controls the tilt movement of the carriage and the angle of the forks relative to the ground. The carriage is a platform located in front of the forklift mast that is used to mount objects to be controlled by the mast.

Horn — Many alarms and signals included on forklifts are automatically engaged. Today, there are many different options for keeping operators, supervisors, and pedestrians safe.

Additionally, forklifts have numerous safety devices distributed throughout the truck. Answer: It counteracts the weight on the forks and provides for the proper weight distribution of the truck. The front wheels act as the fulcrum — or balancing point. And this would cause the lift truck to tip forward — rendering it useless and potentially causing injury. There are two main types of forklift counterweights:. They can also consist of a single metal casting or a hollow metal container with a mix of concrete and metal.

Learn about the different terminology and the various parts of a forklift truck. Use our forklift diagram for reference. Forklifts have many moving parts and pieces that allow the forklift to operate properly. Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job. Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. The forklift mast is the raised vertical support that allows loads to be raised and lowered.

Forklift parts diagram

Additionally, forklifts have numerous safety devices distributed throughout the truck. Answer: It counteracts the weight on the forks and provides for the proper weight distribution of the truck. The front wheels act as the fulcrum — or balancing point. And this would cause the lift truck to tip forward — rendering it useless and potentially causing injury. There are two main types of forklift counterweights:. They can also consist of a single metal casting or a hollow metal container with a mix of concrete and metal. Lift trucks with stack-type counterweights can have as many as six plates stacked, each at 2.

5 minute crafts youtube

Overhead guards may also be reinforced if needed. Depending on amount of use and load size, lift cylinders may need replacing over the life of the truck. There are two main types of forklift tires: Cushion Tires — Generally used for forklifts operating indoors, where surfaces are flat, smooth and consistent. As the workhorses of any operation, forklifts can help to create a safe and efficient environment for moving heavy or bulky loads. For diesel lifts, the tank is located within the chassis like the location on automobiles. The forks on a forklift are used to make direct contact with a load for transport. The cookie is used to store the user consent for the cookies in the category "Performance". The battery can be 12V to 96V, depending on availability. With the help of the levers, we can operate the hydraulic cylinders. This has the lowest lift height maximum. Some trucks have swing cylinders. Find Your Region. The forklift lift cylinder powers the vertical movement of the mast, or the raising or lowering of the forklift carriage and the forks.

Forklifts are complicated.

Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. There will be either 2 wheels for steering in the centre, or as is more common 1 on each rear corner. As they have far fewer moving components than an IC truck, the maintenance and running costs are less. Propane powered forklifts often have the tank externally mounted for easier access. Max Height Alarm — This alarm warns the operator that the lifted load exceeds the maximum rated weight for the lift. There are 4 types of forklift masts :. Table of Contents. The backrest is another surface to rest the load and is connected to the mast. The key difference is that the tilt cylinder controls the tilt movement of the carriage and the angle of the forks relative to the ground. It operates by the engine or battery and uses the counterweight to balance the lifting load. Overhead guards may also be reinforced if needed. It is important to use a load backrest that is designed for the forklift. It is for protecting the operator from any overhanging equipment. For this guide we are focusing on counterbalance forklift parts.

0 thoughts on “Forklift parts diagram”