Fea fusion 360

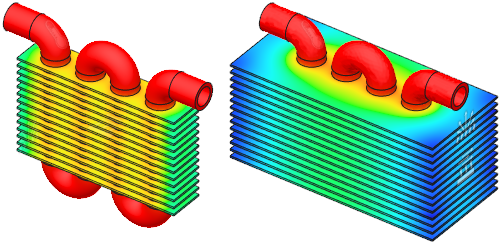

FEA software predicts with dependable accuracy how a product will react to mechanical stress and vibration, fatigue, motion, heat, fluid flow and more, so you can make adjustments before making a prototype. Finite element analysis FEA is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fea fusion 360, fluid flow, and other physical effects.

This area of learning content consists of a series of tutorials to walk you through the simulation process for each analysis type in Fusion The tutorials demonstrate real-world finite element analysis FEA situations. Using the provided CAD models, familiarize yourself with the simulation tools and general workflow habits. All simulation studies run on the cloud, and rely on cloud computational services to do so. Each tutorial shows you how to locate and open the required Fusion model dataset.

Fea fusion 360

Welcome to the Simulation overview. Fusion Simulation is a validation tool that uses finite element analysis FEA to help you understand how a design performs under certain conditions. FEA is a computerized method for predicting how a real world object reacts to forces, heat, vibration, and so on. It shows whether an object will break, wear out, or work the way it was designed. It is called analysis, but in the product design cycle it is used to predict what is going to happen when the product is used. You can use FEA to reduce the need to create physical prototypes and perform destructive tests. For this reason, FEA is considered as a digital prototyping method. Save time-to-manufacture, in the Simulation workspace, as you experiment with virtual design variations or adapt your model to changing design requirements. Use the tools in the Simulation workspace to minimize physical prototyping and destructive testing requirements. The tools in the Fusion Simulation workspace help you to:. Compare the effects of different materials and different conditions such as loads and constraints. Alter the mass and geometry of an object to change its natural vibration frequencies, avoiding the frequencies of operating loads to prevent resonance.

Naver Privacy Policy.

.

I need to create Static Stress Analysis and test the welds in the assembly. Go to Solution. We do not have a specific contact type for just bonded edges. I would recommend checking out this class from Autodesk University on the topic of simulating welds. I get a page following that link. It appears to have moved to here. Fusion Overview. By role Machinist. Mechanical Engineer. Industrial Designer.

Fea fusion 360

I am working on a project and intend to perform FEA simulations on certain parts of the project. I will use the 3D printing process to produce the parts that make up this project. Before that I would like to run the simulations. I was searching the library and could not assimilate a material with the same physical properties of the PLA If I'm wrong you can correct me. So I took the liberty to create the material for my library and I am using the material information provided by Ultimaker to observe the images below:. When I was adding the properties I ended up getting a conflict and I do not know what are the main factors for the change. Some community expert could help me with this setup. Go to Solution.

Europa universalis 4 season pass

Japan Privacy Policy. Dynatrace We use Dynatrace to collect data about your behavior on our sites. Find a reseller. Clearbit Clearbit allows real-time data enrichment to provide a personalized and relevant experience to our customers. We use the data that we provide to Wunderkind to better customize your digital advertising experience and present you with more relevant ads. Facebook We use Facebook to deploy digital advertising on sites supported by Facebook. Improve your experience — allows us to show you what is relevant to you These cookies enable us to provide enhanced functionality and personalization. We use the data that we provide to G2Crowd to better customize your digital advertising experience and present you with more relevant ads. We use the data that we provide to Google Analytics Advertising to better customize your digital advertising experience and present you with more relevant ads. Adobe Analytics We use Adobe Analytics to collect data about your behavior on our sites. It shows whether an object will break, wear out, or work the way it was designed.

Autodesk Fusion for personal use includes cloud-based design and 3D modeling tools, as well as the following limited functionality:. Join over 4. Autodesk Fusion for personal use is free online CAD for qualifying non-commercial users as a 3-year subscription.

You may experience a different version of our sites based on feature testing, or view personalized content based on your visitor attributes. G2Crowd Privacy Policy. Sign in. Launch Darkly We use Launch Darkly to collect data about your behavior on our sites. We use session recording to help us see how you interact with our sites, including any elements on our pages. Learn about Autodesk manufacturing solutions. Launch Darkly Privacy Policy. StackAdapt Privacy Policy. The difference today is that the algorithms driving simulation software can perform FEA calculations much faster and can test for multiple force effects simultaneously. Bidtellect We use Bidtellect to deploy digital advertising on sites supported by Bidtellect. Yes No.

Quite good question