Dt466 engine specs

It looks like you are visiting our site on a browser that is really old.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions.

Dt466 engine specs

How much horsepower can a make reliably for highway use? I was thinking of a dual turbo set-up and some pump and injector improvements. I am looking at building a hot shot type rig and using at least a double overdrive for fuel mileage and still be able to run the speed limit up hill loaded. I see several Dodges and Fords with chips and other mods and got to wondering, why not one of these? If you choose to increase much more than that you will start to have some reliability issues. The more you increase the HP the greater your cooling needs will become, especially on an uphill grade. Marine applications don't count because keel coolers have the whole ocean for heat exchange. The ease of increase depends upon which pump you have. The electronic pump is a software upgrade. Inline mechanical pumps are easier to increase than the mechanical rotary type pump. Depending on what transmission you have behind your DT will also determine how much of an increase in HP you can use. More than that you will need the HT-series if you want reliability. Stick shifts will be limited to the size of the clutch.

We're so happy you're here! More than that you will need the HT-series if you want reliability. The factory used different pumps with the different parts to achieve those ratings.

The goal for the series engines, in particular, was to replace the aged yet highly venerable DT, which International planned to phase out of production. In virtually every application it was placed in service in, the ci I-6 predecessor had proven near-bulletproof, typically guaranteeing its owner 10, loyal operating hours before requiring an overhaul. Needless to say, the ci, ci, and ci power plants had a lot to live up to. While the DT underwent various changes and updates over the years, foundationally much remained the same. The latter wet-sleeve technology brought heavy-duty durability to the medium-duty diesel segment. As a bonus, the wet sleeve essentially makes each cylinder a stand-alone unit, which means repairs and rebuilds can be executed affordably and in-frame.

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which very much needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling. It included the D 4.

Dt466 engine specs

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which needed a diesel upgrade. The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling.

Cplaya2 leaks

The P pump DT was actually used in select applications through the model year, but these are uncommon. The D debuted in the tractor. They all received new, twin turbochargers, with higher-rated versions of the MaxxForce DT and all MaxxForce 9 and 10 engines receiving intercooling and aftercooling. Share 0. They were thoroughly modern and built on new tooling in the Melrose Park, Illinois, plant that was the home of the Construction Equipment Division. This design is opposed to parent bore engines, where the cylinder walls are machined out of the bores cast into the block. Just as the DT and IE engines had shared a common block and the same 5. Modifications from the civilian versions included diamond-coated metal nitride coating injectors [ citation needed ] to enable the engines to run on JP-8 fuel. Another truck I had was rated at hp and generated 18psi boost. If you have repowered a truck that didn't have the DT in it from the factory, increasing the HP can also cause driveline and chassis problems. Additionally, they state that the hardened cylinder sleeve is more durable and wear resistant than a softer, cast-in wall. Contents move to sidebar hide. Not an exact science, but a guideline.

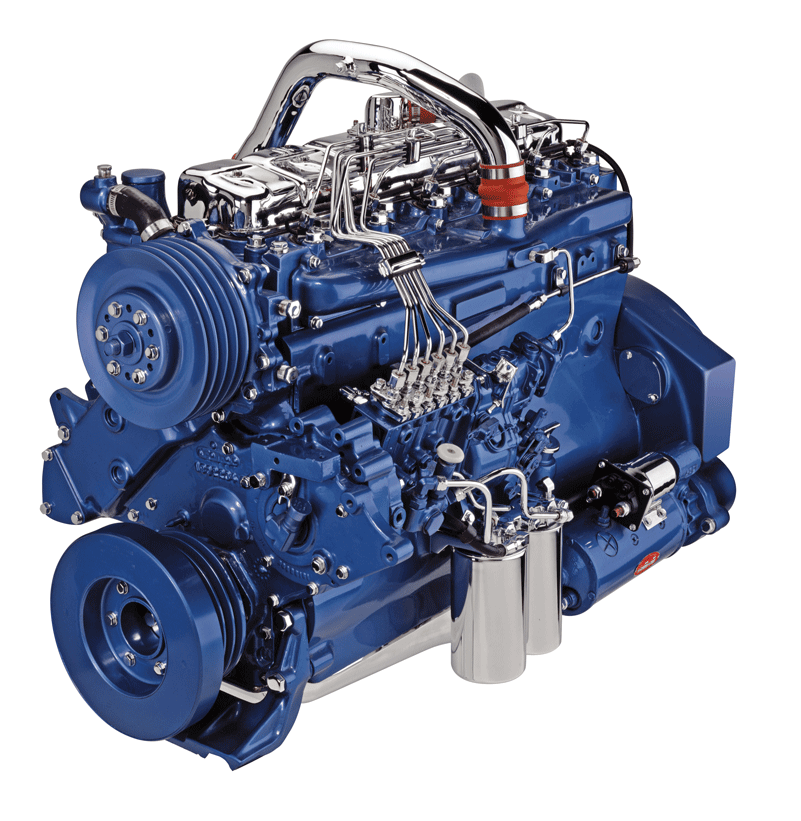

The DT engine is a 7. The engine was first produced in by International Harvester, which later became Navistar International. In this article, we will explore the history, specs, features, and common problems of the DT engine, as well as answer some frequently asked questions.

The idea of offering a premium wetsleeved turbo-diesel in a medium duty line that could be overhauled in-chassis like a heavy-duty truck was a new one and IH hit paydirt with it. They are oringally from farm tractor useage adpted to truck useage and they were very scussedfull with it. Stick shifts will be limited to the size of the clutch. But to meet the stricter EPA emissions standards that had gone into effect in , International switched the bulk of its on-road DT engines over to the Caterpillar-designed HEUI injection system in the HEUI acronym representing hydraulically actuated, electronic controlled unit injector. Also, damage to the cylinder wall requires more extensive work to repair. Download as PDF Printable version. It was first used in four-wheel-drive tractors. Upgrades to fuel injectors, the EGR system, and cooling were also part of the modifications. If you have any questions check out our FAQ Page. How much power you want depends on how much you want to spend.

Excellent phrase and it is duly

Thanks for the information, can, I too can help you something?