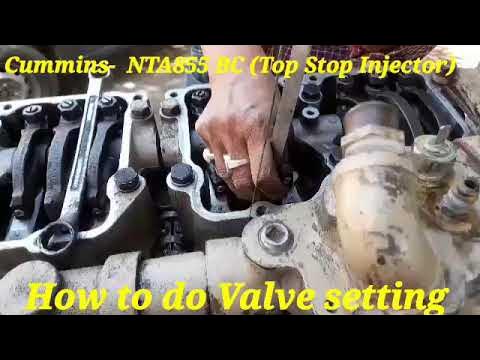

Cummins top stop injector adjustment

We'll discuss the theory and procedures for setting injector plunger travel using the dial indicator method D. Included is the recommended procedure for checking and adjusting crossheads.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions.

Cummins top stop injector adjustment

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Forums Bookmarks New posts Search forums. What's new New posts New profile posts Latest activity. Members Current visitors New profile posts Search profile posts. Vendor Spotlight. Log in Register. Search titles only. Search Advanced search…. New posts. Search forums.

Crankshaft firing order positions are identified by the valve set marks. Venturi Manual Venturi Manual.

Log in. Sign up. Home Forums Farming Community Tractors. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Can you use either one? Mine is a big cam 1.

This post is mainly written to introduce how to adjust crosshead, injector and valves of Cummins NT diesel engines correctly. Pay attention to reading and you will learn more. Crosshead Adjustment. Note: Crosshead adjustment should always be made before attempting to adjust the valves. Loosen the locknut on the crosshead adjusting screw. Turn the adjusting screw out at least one turn. Hold the crosshead down against its mating valve stem. Turn the adjusting screw back in until it touches the valve stem.

Cummins top stop injector adjustment

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going.

Deseo 2013 movie download

The journals and marks are spaced apart. This action depresses the actuator. It's required to set Top Stop plunger travel, and to torque the splined locknut to 55 ft. After setting injector plunger travel, check and set the crossheads and valve clearances on cylinder number 5. Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Hope this gives you something you can work with. Search forums. The exhaust valve is closed on the base circle and is fully open at peak lift. That's how I do them and I do have the proper tools, this way is just faster and accurate enough. Jump to Page. We get it, advertisements are annoying! About '73 Cummins came up with the NTA engines. Reinstall, torque housings. If you find unacceptable wear conditions on the adjusting components, replace them.

Log in. Sign up.

This is a Top Stop adjustment fixture What's new New posts New profile posts Latest activity. Members Current visitors New profile posts Search profile posts. When removing the gauge, you should still feel a slight drag. Jump to Page. When necessary, retorque them to maintain tolerances. The crankshaft rod journals for cylinders 3 and 4 relate to the "C" mark. I just completed adjusting my NHC top-stop injectors. Misadjusted plunger travel produces a noticeable difference in fuel consumption. It takes two revolutions of the cran kshaft, or , to complete a full fuel injection cycle. Open navigation menu.

Certainly. I join told all above.

I am sorry, that has interfered... I here recently. But this theme is very close to me. I can help with the answer. Write in PM.

On your place I so did not do.