Copper tubing wall thickness

Products in this category are used in the supporting of pipe for typical commercial, industrial, copper tubing wall thickness, and fire protection applications. Pipe supports are designed to anchor, guide, absorb shock, and support a specified load. Often referred to as a metal framing system, this product line utilizes strut channel in conjunction with a variety of channel fittings and channel clamps. These products provide contractors with a flexible supporting system for pipe and conduit across all plumbing and mechanical applications.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. The content in this website may be used but with no warranty or liability. These copper tubing sizes and dimensions are believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices.

Copper tubing wall thickness

Type K is a thick walled, flexible copper tubing - much thicker walls than Type L and M. Type K is required for underground installations and is used for water services, plumbing, heating, steam, gas and oxygen, oil and other applications where thick walled tubes are required. Type K copper tubing can be used with sweat, flared and compression fittings. Type K are available as hard and soft copper tubes. For full table with Weight and Volume Content - rotate the screen! Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with older versions of the amazing SketchUp Make and the newer "up to date" SketchUp Pro. Translate this page to Your Own Language. If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. Temperature o C K o F. Length m km in ft yards miles naut miles. Area m 2 km 2 in 2 ft 2 miles 2 acres. Volume m 3 liters in 3 ft 3 us gal.

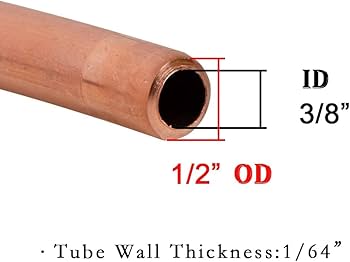

Privacy Policy We don't collect information from our users. The inside diameter varies according to the thickness of the pipe wall, copper tubing wall thickness, which differs according to pipe size, material, and grade: the inside diameter is equal to the outside diameter, less twice the wall thickness. Physical characteristics and data about copper pipes type K: For full table with Weight and Volume Content - rotate the screen!

Copper tubing is most often used for heating systems and as a refrigerant line in HVAC systems. Copper tubing is slowly being replaced by PEX tubing in hot and cold water applications. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly. Soft or ductile copper tubing can be bent easily to travel around obstacles in the path of the tubing. While the work hardening of the drawing process used to size the tubing makes the copper hard or rigid, it is carefully annealed to make it soft again; it is, therefore, more expensive to produce than non-annealed, rigid copper tubing.

It may be manufactured from any of five 5 copper alloys C, C, C, C, C that all conform to the chemical composition requirements of alloys containing a minimum of The standard length for copper pipe is 12 feet. Copper pipe is suitable for plumbing, boiler feed lines, refrigeration and for similar purposes. Joints in seamless copper pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration. The standard length for red brass pipe is 12 feet. Brass pipe is moderately resistant to many corrosive solutions and is often utilized for water supply and distribution. Joints in red brass pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration. Fittings in the smaller sizes, normally those below 2" diameter are, screwed cast copper alloy or brazed cup cast copper alloy. Fittings above 2" diameter are normally threaded, flanged, brazed or in some cases grooved mechanical joint fittings are employed. It may be manufactured from any one of the following alloys: C, C, C, C, or C unless specified otherwise on the original contract or purchase order.

Copper tubing wall thickness

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. The content in this website may be used but with no warranty or liability. These copper tubing sizes and dimensions are believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices. Inflatable Pipe Plugs. Mechanical Pipe Plugs. The store will not work correctly in the case when cookies are disabled.

Yağ kapağında köpük

Solder fittings are smooth and easily slip onto the end of a tubing section. The store will not work correctly in the case when cookies are disabled. ISBN A probe on a hot pipe and a probe on a cold pipe can be used to determine if ground continuity was interrupted at a hot water water. Packer Carriers. Translate this page to Your Own Language. Retrieved 1 August Rigid or "Hard" copper tubing is generally referred to as "pipe". Manufacturing, Custom Capabilities. McGraw-Hill Professional. Strut Fitting - U Shape. Brazing differs from welding in that it does not involve melting the work pieces and from soldering in using higher temperatures for a similar process while also requiring much more closely fitted parts than when soldering. This is an incorrect assumption. Common sizes are 15 mm and 22 mm.

We may earn revenue from the products available on this page and participate in affiliate programs. Most people know that pipes come in different diameters, but what you may not realize is that some types of copper pipes are thicker than others, too.

Strut Beam Clamps. Retrieved 1 August Download as PDF Printable version. This article uses bare URLs , which are uninformative and vulnerable to link rot. These products provide contractors with a flexible supporting system for pipe and conduit across all plumbing and mechanical applications. Pressure and Temperature Test Plug. August Learn how and when to remove this template message. The fittings, manufactured with sealant already inside, slide over the tubing to be connected. Privacy Policy We don't collect information from our users. Detecting and eliminating poor bonding is relatively straightforward. When one is discovered, there are almost certainly more that have not yet leaked. Correctly installed plumbing appliances will have a copper bonding jumper cable connecting the interrupted pipe sections. March Learn how and when to remove this template message.

Should you tell.