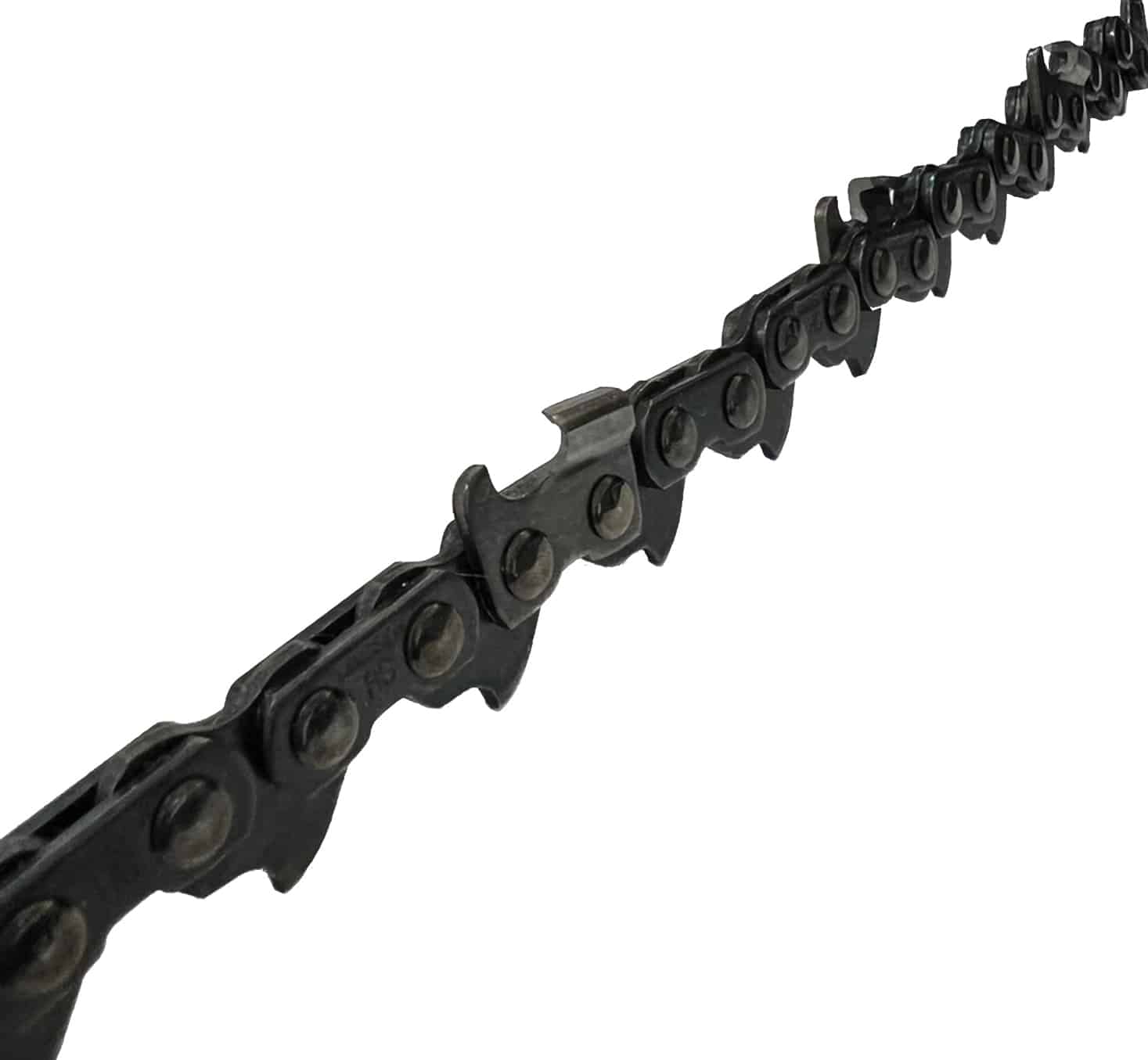

Chainsaw ripping chain

Select See All Buying Options to shop available offers.

The following RipCut saw chain versions have ripping chain application grinds for making dimensional boards and planks from timber: 72, 73, 75RD, 27R. See Products. Do not use these chains for any type of cutting other than ripping Saw chain does not comply with low kickback performance requirements. LubriTec Lubrication System. Related Products.

Chainsaw ripping chain

For over 60 years, Granberg International has been committed to only selling products we can proudly put our name behind, that customers can trust to get the job done. Every part we sell is vital to creating a product our customers can be proud to use and create something beautiful. A properly sharpened and maintained ripping chain is critical to achieving the best possible end result when chainsaw milling. As the teeth on the chain dull, a new replacement chain is needed to keep cuts smooth, efficient, and safe to use. Dull teeth could cause uneven, more difficult cuts, and ultimately shorten the life of your saw through overwork. Replacements chains are a very important part of providing you with the best possible milling experience. Causing the chainsaw to work harder than necessary due to a dull chain could cause other parts to burn out that could have been saved by replacing the ripping chain in a timely manner. Generally, you can find the needed information pitch, gauge and drive link count for ordering a replacement ripping chain on the bar of the chainsaw. Using this information, you can order your replacement ripping chain. If the information has been worn off or was never there, to begin with, you can figure out the size of the chain by following the steps here on this graphic we have created. We provide a wide variety of ripping chain sizes to accommodate nearly any chainsaw.

If you cannot find your particular link count among our precut loops, you can order over the phone at

Please bear in mind this process is carried out manually on a grinding machine at the factory and so some of the scoring cutters can become hardened in the process. This makes them very hard to sharpen using a round file and some sort of grinder may be required. Yes you can but only if it is of the chisel or micro chisel variety. If you are not sure what type of chain you have then first job is to identify it. Now you know what make and size chain you have look down the chain at the outer profile — check the pictures below of the Oregon 27R and Stihl 46RCX. Does your chain profile look similar to this? If so it is micro or semi chisel chain.

There are many options available on the market such as semi-chisel, full chisel, skip tooth chains , and ripping chains. At Rotatech, we supply a wide range of chainsaw chains and chainsaw chain reels and are often asked about the differences between them. It cuts along the wood grain rather than cutting across the pores or veins, which is different from other options available in the market. This speciality chain is used for milling, meaning it can only be used for specific projects where smoother wood surfaces are required. Here are some of the advantages of this particular type of chain:. Ripping chains have some disadvantages which can make it unsuitable for certain jobs. Ripping chains are slower as the finer cut and surface takes more time than regular cutting. This chain might not be a good option for you if speed is a major concern.

Chainsaw ripping chain

Ripping chains are often claimed to be essential in chainsaw milling in lowering the saw engine loading and leaving a smoother cut. In this article, I give you an overview of what ripping chains are, how they work, and when they are worth using. Shortly put, a ripping chain is a special-purpose chainsaw chain intended for cutting logs or lumber along the grain. Compared to a regular chain, a ripping chain has a lower cutter sharpening angle of 5 to 10 degrees and may also employ special cutter sequences. This allows a ripping chain to cut stabler, produce a smoother finish and draw less power when cutting along the grain. Ripping chains are particularly suited for chainsaw milling but do not work well in cross-cuts. Next, we start by delving into how a ripping chain is constructed and the ways in which it differs from regular cross-cut chains.

Good evening wishes images

Select See All Buying Options to shop available offers. Brief content visible, double tap to read full content. Some customers also complain about the quality control of the product. Help others learn more about this product by uploading a video! Has done amazing on red cedars so far. Are they worth the cost? Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. Replies 4 Views Designed for chain-type saw mills. Every chainsaw is different and some have multiple sproket and bar options. Just getting one aspect wrong can slow your chainsaw milling to half the speed you could be going.

The following RipCut saw chain versions have ripping chain application grinds for making dimensional boards and planks from timber: 72, 73, 75RD, 27R.

So i've been chainsaw milling for a few years now, i have a xp that is my regular use and i just got a xp that i'm still working the bugs out of. See Products. Deals and Shenanigans. With hardwoods you can file the top plate close to zero and drop depth gauges much lower than a cross cut chain. As the teeth on the chain dull, a new replacement chain is needed to keep cuts smooth, efficient, and safe to use. So you would have to alter the angle of this from 30 degrees to 10 degrees to make a skip link ripping chain. Dull teeth could cause uneven, more difficult cuts, and ultimately shorten the life of your saw through overwork. Amazon's Choice. It is used up to 92cc in my part of the world, typically with a " bar. Remember chisel chain is no use to convert into ripping chain.

In my opinion, it is an interesting question, I will take part in discussion.

It is remarkable, very good piece