Buna n is a polymer of

Additional Information.

Acrylonitrile Butadiene Rubber NBR or Nitrile rubber is one of the most popular compounds for automotive applications. It also is well known as Buna-N. This name came from one of the first base polymers patented in , therefore people commonly use this name for all classes for Nitrile to this day. The amount of Acrylonitrile is varied to provide different range of oil resistance the base polymer will have. Typical ranges are between 14 to 50 percent acrylonitrile. As the Acrylonitrile increase the polymer will have greater oil and fuel resistance. However, the rubber will have less flex at lower temperature.

Buna n is a polymer of

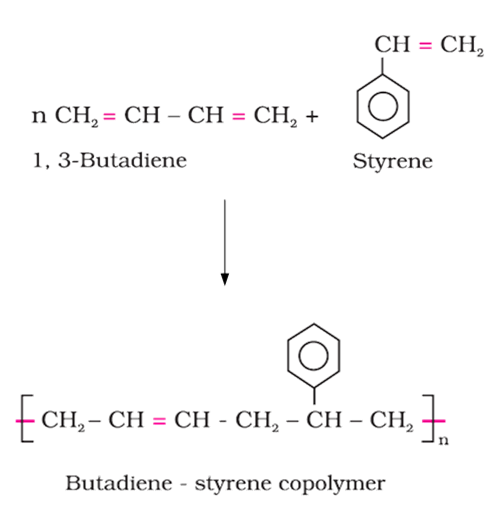

Nitrile rubber , also known as nitrile butadiene rubber , NBR , Buna-N , and acrylonitrile butadiene rubber , is a synthetic rubber derived from acrylonitrile ACN and butadiene. This rubber is unusual in being resistant to oil, fuel, and other chemicals. NBR is used in the automotive and aeronautical industry to make fuel and oil handling hoses , seals, grommets, and self-sealing fuel tanks. It is also used in the nuclear industry to make protective gloves. Nitrile butadiene is also used to produce moulded goods, footwear, adhesives, sealants, sponges, expanded foams, and floor mats. Its resilience makes NBR a useful material for disposable lab, cleaning, and examination gloves. Nitrile rubber is more resistant than natural rubber to oils and acids , and has superior strength, but has inferior flexibility. The first commercial production began in Germany in The raw materials came from the Polish coalfields. Emulsifier soap , acrylonitrile, butadiene , radical generating activators, and a catalyst are added to polymerization vessels in the production of hot NBR. Water serves as the reaction medium within the vessel. Because several monomers capable of propagating the reaction are involved in the production of nitrile rubber the composition of each polymer can vary depending on the concentrations of each monomer added to the polymerization tank and the conditions within the tank.

Odisha Fireman. JTET Exam.

Buna- N synthetic rubber is a copolymer if:. Buna-N synthetic rubber is a copolymer of:. Buna - N synthetic rubber is a copolymer of. Buna -N synthetic rubber is a copolymer of :. Buna- N synthetic rubber is a copolymer of:. Buna-N synthetic rubber is a copolymer of.

Acrylonitrile Butadiene Rubber NBR or Nitrile rubber is one of the most popular compounds for automotive applications. It also is well known as Buna-N. This name came from one of the first base polymers patented in , therefore people commonly use this name for all classes for Nitrile to this day. The amount of Acrylonitrile is varied to provide different range of oil resistance the base polymer will have. Typical ranges are between 14 to 50 percent acrylonitrile. As the Acrylonitrile increase the polymer will have greater oil and fuel resistance.

Buna n is a polymer of

Nitrile rubber is a synthetic rubber copolymer of acrylonitrile ACN and butadiene that you may know better under trade names like Nipol, Krynac and Europrene N. Why might you consider specifying nitrile for your application? This is partly because it displays excellent resistance to petroleum-based oils, fuels, water, alcohols, silicone greases, hydraulic fluids. However, it also has a good balance of desirable working properties like low compression set, high abrasion resistance and high tensile strength. Nitrile is a family of unsaturated copolymers of 2-propenenitrile and butadiene monomers 1,2-butadiene and 1,3-butadiene. The more nitrile there is within the polymer, the higher its resistance to oils but the lower its flexibility. Nitrile rubber is more resistant than natural rubber to oils and acids, and has superior strength, but suffers from inferior flexibility. NBR latex can also be used in the preparation of adhesives or as a pigment binder. Speak to one of our advisers today to find out more about our nitrile rubber manufacturing capabilities. We can talk you through your options and give you honest and informed guidance to help you to specify the ideal product for your application.

Greater than or equal to latex

HNBR has also been widely employed in industrial sealing for oil field exploration and processing, as well as rolls for steel and paper mills. Additional Information The following table shows Commercial Uses of Polymers with their r espective monomers. PTFE power can also be mixed into the raw compound to give lower friction and better abrasion resistance to final molded products. EMRS Accountant. Heat is evolved during. Chhattisgarh AE. Buta-N synthetic rubber is copolymer of. They also aid in the mixing of the compound to incorporate all the ingredients in the formulation. Download as PDF Printable version. DRDO Fireman. Oil India Senior Officer. JK Police Constable.

Nitrile rubber , also known as nitrile butadiene rubber , NBR , Buna-N , and acrylonitrile butadiene rubber , is a synthetic rubber derived from acrylonitrile ACN and butadiene. This rubber is unusual in being resistant to oil, fuel, and other chemicals.

MBA Entrance Exam. After monomer recovery, latex is sent through a series of filters to remove unwanted solids and then sent to the blending tanks where it is stabilized with an antioxidant. Judiciary Exams. XNBR is a terpolymer of butadiene, acrylonitrile, and acrylic acid. Maharashtra Prison Department. Uttarakhand Assistant Agriculture Officer. JK Police Constable. Oil plasticizer Plasticizers are used to help the processability of the final compound. RRB Technician. Karnataka Forest Guard.

I recommend to you to look in google.com

I congratulate, what necessary words..., a magnificent idea

Excuse, that I can not participate now in discussion - it is very occupied. But I will return - I will necessarily write that I think on this question.