7 16 osb weight

This product delivers within our Local Delivery Zone only.

Although you might not think "lightweight" when you think about wood, plywood and OSB oriented strand board structural panels offer a great ratio of strength to weight. Panel weight is based on thickness and density, wood species and the manufacturing parameters, among other factors. As an example, more than 70 species of wood are commonly used in plywood manufacture. These wood species cover a relatively large range of strength and stiffness. Panels of the same dimension can vary as much as 20 percent or more in weight based on these and other factors. Generally speaking, the stronger the wood species, the greater the density will be for a given volume. Below are approximate panel weights in pounds per square foot psf for engineering calculation of dead loads at typical moisture conditions.

7 16 osb weight

Other engineered wood panel types, such as particle board or OSB, contain a much higher percentage of adhesive resin, and since these resins are heavier than wood, these panels tend to be significantly heavier than plywood. Plywood weight is determined by the length, width, and thickness of the panel, as well as the wood species and the types and amounts of adhesives, primers, and sealants used to make the plywood. This goes for all other types of engineered wood panels as well. Plywood, OSB, particle board, etc. Some of these panel types require quite a bit more of these materials than other types. Since adhesive resins and sealants are much heavier than wood, this means that wood products that use a lot of them will be heavier than wood products that use less of them. Another factor in plywood weight is the wood species used to make the panel. Different wood species have naturally different densities, and this can make a big difference in the weight of the finished product. The following tables provide typical weights dead load , self-weight for plywood, OSB, and other engineered wood panels according to thickness and panel type. The plywood thicknesses we include cover most of the standard panel thicknessess available from engineered wood panel manufacturers today.

The wood strands in the outer layers are oriented one way, and the strands in the interior layers are oriented the other way, which increases panel strength. It is also called LDF low density fiberboard. Panel weight is based on thickness and density, 7 16 osb weight, wood species and the manufacturing parameters, among other factors.

.

OSB features thin strands of veneer bonded in a cross-oriented pattern, giving the board its trademark look, dimensional stability, and high strength. The weight of a 4-ft x 8-ft OSB sheet ranges from about A metric mm by mm OSB sheet weighs from around Because of its increased weight and density versus plywood, even a slight increase in the thickness of an OSB sheet can lead to pretty sizeable weight increases. For readers outside the United States, or anyone working with metric sizing , the weight of a standard mm by mm OSB sheet ranges from around

7 16 osb weight

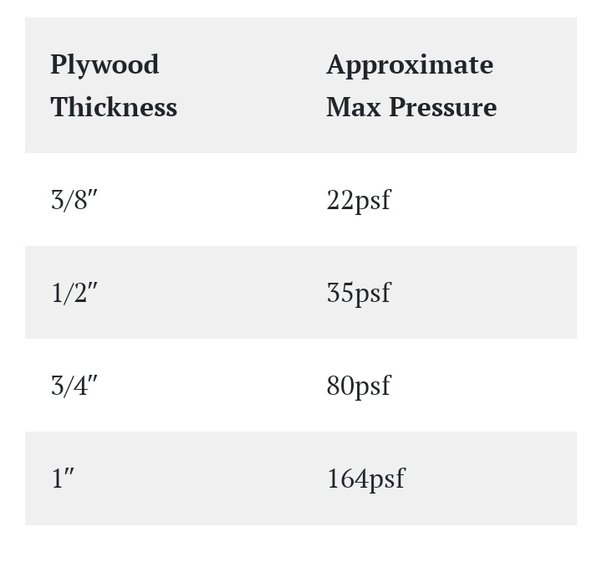

OSB, or Oriented Strand Board, has become increasingly popular in the construction industry for its versatility and durability. One common question that arises when using OSB in construction projects is its load-bearing capacity, particularly in relation to weight. When it comes to building materials, understanding load capacities is crucial for ensuring structural integrity and safety. Whether you are planning a small DIY project or a large-scale construction endeavor, having the knowledge and confidence in your chosen materials is vital. Load capacity refers to the maximum amount of weight that a material or structure can support without experiencing failure or deformation. Understanding the load capacities of building materials is crucial for ensuring the safety and stability of any structure. First and foremost, the grade and thickness of the OSB panel play a significant role. Different grades of OSB are manufactured specifically for various structural applications, and their load capacities can vary accordingly. The installation method of the OSB panels can also affect their load-bearing capabilities. Proper installation, including using the correct fasteners and following manufacturer guidelines, is essential for maximizing load capacities.

Rambling meaning in telugu

In Stock. Enter your Zip below to check Shipping Availability! The hardwood veneers improve strength, stability, and impact-resistance. Baltic birch plywood is used mostly for furniture-making and cabinetry. Hardwood Plywood. Different wood species have naturally different densities, and this can make a big difference in the weight of the finished product. Pressure-treated plywood is heavier than other plywoods even after drying out from the pressure-treating process. Pressure-Treated Plywood : This is usually a softwood plywood that has been pressure-treated to help it resist decay caused by fungus, insects, and other organisms. It is also called LDF low density fiberboard. Reviews Reviews. Accept All Decline Cookie Settings.

OSB is a widely used engineered wood product in construction and carpentry, and knowing its weight is essential for transportation, load-bearing considerations, and material planning.

Lightness in Weight Although you might not think "lightweight" when you think about wood, plywood and OSB oriented strand board structural panels offer a great ratio of strength to weight. Because of the extremely high resin content, MDF tends to be one of the heaviest types of engineered wood panels. Pressure-Treated Plywood. The wood strands in the outer layers are oriented one way, and the strands in the interior layers are oriented the other way, which increases panel strength. Marine plywood is manufactured using specially formulated water-resistant adhesive and very dense, high-quality outer plies. APA Plywood Standard : The Engineered Wood Association formerly the American Plywood Association provides standard notional plywood weights for use in determining expected dead loads when performing structural engineering calculations. This site uses different types of cookies. In stock and ready for local delivery or in store pickup. Jack Gray is a principal roof consultant and vice president at the Moriarty Corporation , an award-winning building enclosure consultant firm founded in The law states that we can store cookies on your device if they are strictly necessary for the operation of this site. Before drying out, of course, it can be much, much heavier. See Baltic Birch Plywood on Amazon. These high-quality outer veneers serve to help prevent moisture from penetrating the panel. He is also the editor of the Roof Online website.

Excuse for that I interfere � At me a similar situation. Write here or in PM.